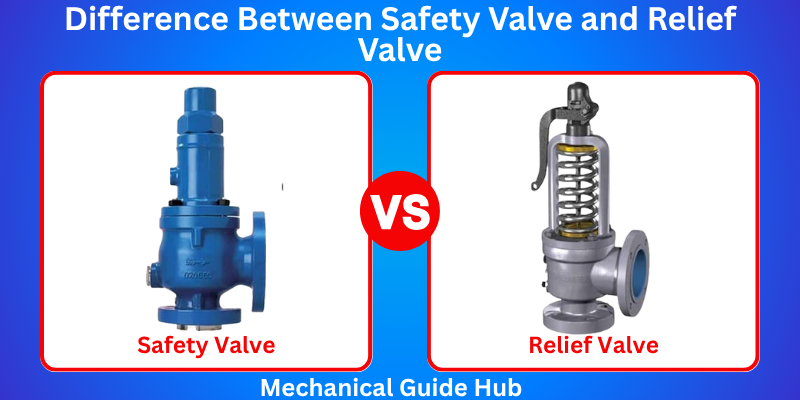

Difference Between Safety Valve and Relief Valve

Published: 23 Jul 2025

Whether you’re working with industrial equipment, steam boilers, or fluid systems, one thing remains critical—pressure control. That’s where safety valves and relief valves come into play. While they may seem similar, they serve different functions and operate in distinct ways.

In this article, we’ll break down the difference between safety valve and relief valve, using real-world use cases, technical comparisons, and engineering insights to help you understand when and where to use each one.

Safety Valve vs Relief Valve: The Key Differences

Safety Valve

- A safety valve reacts quickly to a sudden release. When the pressure reaches its limit, this valve pops open all at once. It is designed to act quickly in an emergency.

- Protects people and equipment from unexpected pressure spikes, particularly in steam or gas applications.

- Commonly used with compressible fluids, including steam, air, and gas.

- Relief valves open gradually, adjusting in small steps as the pressure rises. Their operation is smooth and steady.

- Commonly installed in boilers, steam lines, pressure tanks, and chemical processing units.

- Features a quick-response mechanism that releases pressure within milliseconds.

- Has a fixed pressure setting, usually calibrated by the manufacturer or ASME codes.

- Typically less tolerant of back pressure, which may affect reseating and sealing.

- Must meet stringent standards like ASME Section I (power boilers) or Section VIII (pressure vessels).

- Often includes a manual test lever to verify operation without system shutdown.

- Typically discharged to the atmosphere or vented into stacks, releasing gas or steam safely.

- Designed for high-pressure systems, often up to several thousand psi (e.g., 3% over max allowable working pressure).

- It might close at a pressure lower than its set point, which can cause chatter if not correctly sized.

- If it fails to work, it can lead to explosions or serious injuries.

- To ensure proper operation, the safety valve must be installed upright.

- Requires regular testing and inspection, especially in steam and high-risk systems.

- Safety valves can be manually operated. This is helpful for testing or emergency releases.

- Used in power generation, refineries, petrochemical plants, and food processing.

Relief Valve

- A relief valve opens slowly and gradually. It kicks in when system pressure reaches above a set limit. It maintains stability by slowly releasing gas or fluid.

- Protects equipment and pipelines from gradual pressure increases, mainly in liquid systems.

- An ideal choice for systems dealing with incompressible liquids like water, oils, or chemicals.

- Operates proportionally and opens gradually as the pressure exceeds the set limit.

- Common in hydraulic systems, fuel pumps, oil lines, and cooling circuits.

- Responds more slowly, allowing controlled pressure reduction over time.

- Some designs allow adjustable pressure settings, ideal for precision-based systems.

- Can be balanced or spring-loaded to reduce the backpressure on the return line.

- Generally, it complies with industry norms such as API 520/526, ISO 4126, or standards tailored to liquid applications.

- Usually does not include a test lever—meant to operate only under automatic pressure response.

- Usually connected to a return line or tank, especially in hydraulic or closed-loop systems.

- Typically used where systems can handle a 10% rise above normal operating pressure.

- Offers stable reseating, making it more suitable for applications requiring pressure fluctuation control.

- Failure may cause equipment failure or fluid leakage, but it is usually less catastrophic.

- Can sometimes be installed horizontally, depending on the design and application.

- Also need maintenance, but generally have a longer service interval due to less aggressive operation.

- Relief valves cannot be opened by hand. They are only responsive to system pressure.

- Used in oil & gas pipelines, chemical dosing, fire protection systems, hydraulic presses.

Conclusion:

Choosing between a safety valve and a relief valve isn’t just about preferences-it’s about safety, performance, and reliability. If your system needs slow and steady pressure control, a relief valve is a good option. But if you’re dealing with high-risk operations where even a slight delay can cause harm, a safety valve is the better choice.

In short, relief valves protect equipment. Safety valves protect lives. That’s why valve experts and industry leaders always stress knowing the difference. The right valve doesn’t just save machines—it can save entire operations from disaster.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks