Different Types of Lathe Machine Operations

Published: 3 Oct 2025

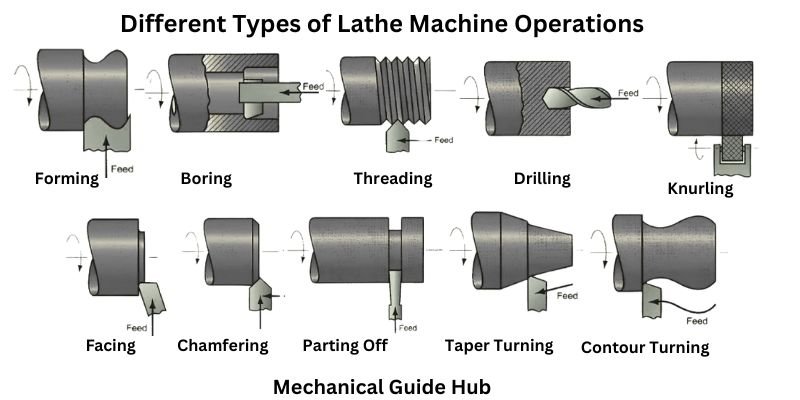

A lathe can carry out multiple operations depending on the cutting tool and workpiece setup. Below, we will discuss the most common lathe machine operations in detail.

Types of Lathe Machine Operations

1. Turning

Turning is the most common lathe operation. It reduces the diameter of a rotating workpiece by removing material from its outer surface. This process is used to create cylindrical parts with smooth and accurate finishes, such as shafts and rods.

a) Taper Turning

Taper turning involves shaping the workpiece so its diameter gradually decreases along its length. This is often done to produce cone-shaped components like drill shanks or machine tool spindles. It can be achieved by setting the tool at an angle or using special attachments.

b) Step Turning

Step turning creates multiple cylindrical sections with different diameters along the workpiece. Each step is cut to a specific measurement, giving the appearance of “steps.” This process is widely used in parts like stepped shafts and axles.

c) Chamfering

Chamfering removes sharp edges or burrs from the ends of a workpiece. A beveled surface, usually cut at a 45° angle, makes the part safer to handle and easier to fit into other components. It also improves the appearance of the final product.

e) Parallel Turning

Parallel turning is performed to reduce the diameter of a workpiece uniformly across its entire length. The cutting tool moves parallel to the axis of rotation, resulting in a smooth, cylindrical finish. This method is used in creating pins, rollers, and rods.

f) Contour turning

Contour turning shapes the workpiece into complex curves or profiles. The cutting tool follows a pre-defined path to produce smooth contours. This operation is useful in manufacturing decorative components and custom machine parts.

2. Facing

Facing cuts the end of the workpiece flat and smooth. It reduces its length and ensures the face is perpendicular to the axis of rotation. This process is usually the first step in preparing a workpiece for further machining.

3. Threading

Threading creates helical grooves on the surface of the workpiece, forming external threads. These threads are used for screws, bolts, and fasteners. Internal threads can also be made using a tap or special threading tools.

4. Grooving

Grooving produces a narrow channel on the surface of the workpiece. It can be external or internal, and it is often used to make seats for O-rings, snap rings, or other locking devices. Grooving tools are specifically designed for precision cutting.

5. Knurling

Knurling is a surface-finishing process that produces a rough, patterned texture. The diamond or straight-line patterns improve grip on tools, handles, and knobs. It also enhances the appearance of the component.

6. Parting

Parting is used to cut a workpiece into two sections. The parting tool is fed perpendicular to the axis of rotation until it separates the material. This operation is essential when making washers, rings, or cutting excess stock.

7. Sanding

Sanding smoothens the surface of the workpiece using sandpaper or an abrasive tool. It removes fine marks and prepares the component for painting, coating, or final polishing. This is one of the last finishing operations.

8. Reaming

Reaming enlarges a previously drilled hole and improves its surface finish. It provides a highly accurate diameter that drills alone cannot achieve. Reaming is commonly used in the precision engineering and automotive industries.

9. Tapping

Tapping produces internal threads in a drilled hole using a tapping tool. This operation allows screws and bolts to fit securely into the part. It is a crucial step in manufacturing components that require threaded joints.

10. Drilling

Drilling is performed to make round holes in the workpiece. A drill bit mounted in the tailstock or tool post is fed along the axis to create the hole. Drilling is often the first operation before reaming, tapping, or boring.

11. Boring

Boring enlarges existing holes and corrects their alignment. It ensures a precise diameter and smooth internal surfaces. Boring is often used in engine cylinders, pipes, and other components where accuracy is critical.

Conclusion

The lathe machine is a must-have in any workshop because of its ability to perform multiple operations with precision. From turning and facing to advanced processes like boring and threading, each method plays an important role in creating accurate and functional components. By mastering these lathe operations, machinists can achieve both efficiency and quality in their work.

FAQs

A lathe can perform more than 15 operations, including turning, facing, drilling, threading, boring, and reaming.

Machining operations include cutting, drilling, shaping, milling, turning, grinding, and finishing processes.

The seven common operations are turning, facing, grooving, threading, parting, drilling, and boring.

The 15 operations include turning, taper turning, step turning, chamfering, parallel turning, contour turning, facing, threading, grooving, knurling, parting, sanding, reaming, tapping, drilling, and boring.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks