What Is a Snap Gauge? Types, Uses, and How It Works

Published: 2 Jul 2025

Have you seen tools that check if a part is the right size? A snap gauge does just that. It’s quick, easy to use, and helps ensure parts are not too big or too small. In this post, you’ll learn what a snap gauge is, the types, how it’s used, and why it’s helpful in workshops and factories.

What is a Snap Gauge?

A snap gauge is a tool used to quickly check if a part is the correct size. It’s also known as a gap gauge or a GO and NOGO gauge. It is used to measure the outer size of cylindrical and non-cylindrical parts.

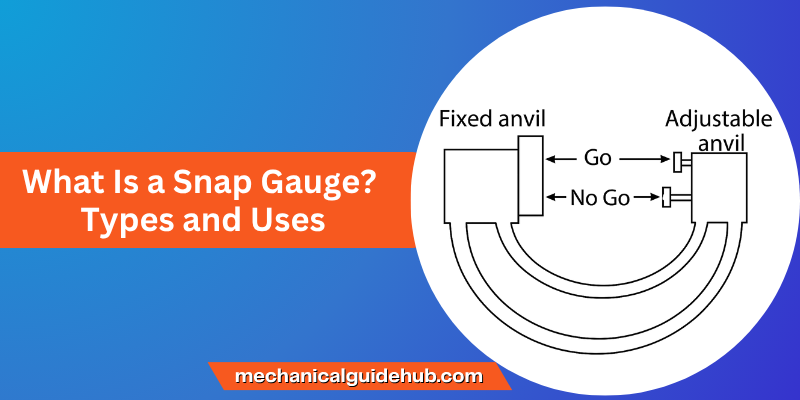

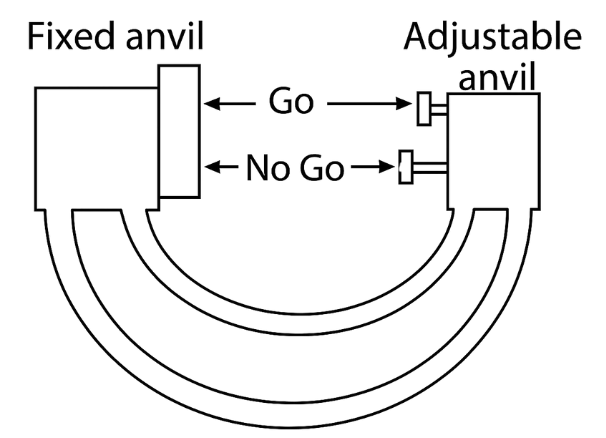

Snap Gauge Diagram

The tool has a C- or U-shaped frame with two fixed measuring gaps:

- GO side – slightly larger, check if the part fits. If it passes, the part is acceptable.

- NOGO side – slightly smaller. If the part passes this side too, it means it’s too small and should be rejected.

Snap Gauge Types

Some common Types of Snap Gauges are as follows:

1. Fixed Snap Gauge

It has a set size. Used for one specific part size.

2. Adjustable Snap Gauge

It can be resized. Useful for checking different sizes.

3. Digital Snap Gauge

It shows the reading digitally on a screen. More modern and precise.

4. Dial Snap Gauge

It has a dial to show small changes. Good for close checks.

Each type has its job, but all aim to check size quickly and clearly.

Snap Gauge Is Used For

So, what is a snap gauge used for? Here’s where it shines:

- Checking whether the part fits the size range.

- Quality control in factories

- Fast inspection during production

- Measuring outer dimensions of rods, shafts, and cylinders

Snap gauges save time and reduce errors. That’s why they’re popular in industries like automotive, aerospace, and tool manufacturing.

How to Use Snap Gauge

Using a snap gauge is simple:

- Hold the gauge in one hand.

- Place the part between the jaws.

- Check if it goes through the GO side and stops at the NO-GO side.

- If it fits, the size is correct.

No guesswork. No complex reading. Just a clear pass or fail.

Conclusion

Snap gauges may look simple, but they’re smart tools. They help check sizes fast and right. Whether you’re working in a factory or learning about tools, knowing how a snap gauge works is a good step. Want fast and reliable checks? Snap gauges are your answer.

FAQs

The GO side checks the maximum limit. If the part fits, it means it’s not too big.

Snap gauges don’t have a traditional least count like vernier tools. They are pass/fail tools based on preset limits.

Used in manufacturing, quality checks, automotive, and mechanical workshops to control part sizes.

Snap gauge prices vary by type. Fixed types cost $10–$50, while digital or dial types can reach $200 or more.

It is used to check the outer diameter or thickness of parts, especially during mass production.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks