Different Types of Pipe Wrench and Their Uses

Published: 10 Oct 2025

Pipe wrenches are one of the most important tools in plumbing and mechanical work. They are designed to grip and turn metal pipes securely without slipping. Understanding the types of pipe wrenches and their uses can help you pick the perfect one for your task, whether you’re tightening a fitting or loosening a stubborn joint. From adjustable to chain pipe wrenches, each type has its unique design and purpose that make it suitable for different situations. A pipe wrench is often called a plumbing wrench because of how essential it is for pipe installation and maintenance work.

What is Pipe Wrench

A pipe wrench is a heavy-duty hand tool used to turn, tighten, or loosen soft iron pipes and fittings. It features serrated jaws that dig into the pipe’s surface, ensuring a firm hold when applying force. The wrench works on a simple lever principle, giving you the power to move even the most stubborn pipes. It’s a must-have tool for plumbers, construction workers, and anyone working with piping systems.

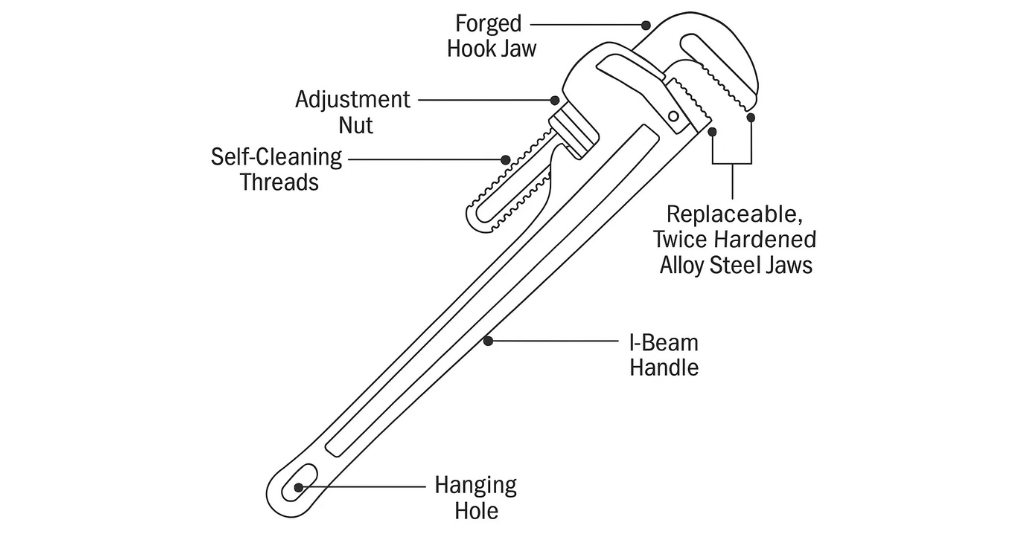

Pipe Wrench Parts Name

Every pipe wrench is built for performance and durability, consisting of the following key parts:

Forged Hook Jaw: The upper jaw that tightly grips the pipe for a strong turning force.

Heel Jaw: The lower fixed jaw that supports the hook jaw while maintaining balance.

Adjustment Nut: Used to open or close the jaw gap, to fit different pipe sizes.

Spring Assembly: Keeps both jaws properly aligned for smooth adjustment.

Self-Cleaning Thread: Ensures easy movement of the adjusting nut and prevents dirt buildup.

I-Beam Handle: A strong yet lightweight handle design for better grip and control.

Twice-Hardened Alloy Steel Jaw: Provides maximum durability and wear resistance for long-term use.

These parts together make the pipe wrench a reliable and long-lasting plumbing wrench for all kinds of pipework.

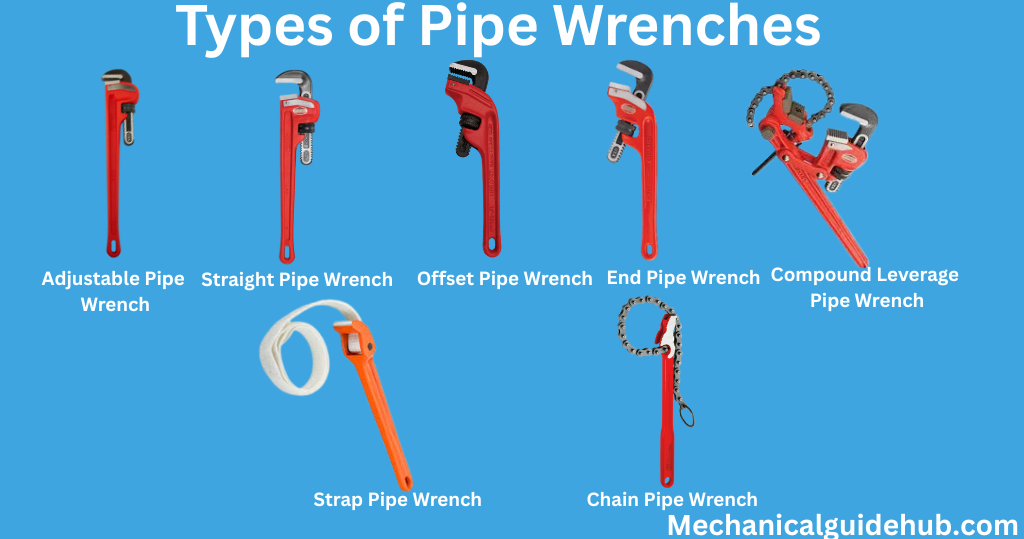

Types of Pipe Wrench

Pipe wrenches are essential tools used in plumbing, construction, and maintenance work. They come in different types to suit various tasks, from tightening small pipes to handling heavy-duty fittings. Each type offers unique features that make it perfect for specific jobs. Below are some common types of pipe wrench and their uses.

1. Adjustable Pipe Wrench

The adjustable pipe wrench is the most commonly used type. Its jaw size can be easily adjusted using a nut, making it suitable for pipes of various diameters. This wrench is perfect for general plumbing repairs and installations in homes and workshops. Its versatility and ease of use make it a go-to plumbing wrench for both professionals and DIY users.

2. Straight Pipe Wrench

The straight pipe wrench is the traditional design invented by Daniel Stillson in 1869. It has a straight handle and jaws that are aligned with the body, providing a strong and direct grip on pipes. This wrench is available in multiple sizes, ranging from small household models to large industrial versions. It’s ideal for everyday plumbing and maintenance work on standard pipe fittings.

3. Offset Pipe Wrench

An offset pipe wrench has its jaws set at an angle, allowing access to tight or awkward spaces where a straight wrench cannot fit. This makes it especially useful for working on pipes near walls, corners, or close to the ground. The angled design improves leverage and comfort, reducing strain during tough jobs. It’s a favorite choice among plumbers who often deal with confined installations.

4. End Pipe Wrench

The end pipe wrench has jaws positioned at a slight angle to the handle, making it ideal for working on pipes that are close to walls, ceilings, or floors. It provides excellent grip in areas where a straight wrench cannot be positioned properly. This design is particularly helpful in overhead or underground pipe systems. The compact build ensures ease of use without sacrificing strength.

5. Compound Leverage Pipe Wrench

The compound leverage pipe wrench is designed for maximum power with minimal effort. It uses a double-handle system that multiplies the applied force, making it easier to loosen rusted or frozen joints. This wrench is perfect for industrial and heavy-duty applications where extra torque is required. Professionals rely on it when standard wrenches fail to deliver enough gripping strength.

6. Strap Pipe Wrench

The strap pipe wrench features a flexible strap made of rubber, leather, or fabric instead of metal jaws. It wraps around the pipe, providing a secure grip without scratching or damaging the surface. This makes it perfect for working with smooth, polished, or plastic pipes. It’s commonly used for plumbing fixtures made of chrome or PVC, where surface protection is important.

7. Chain Pipe Wrench

The chain pipe wrench replaces the upper jaw with a durable metal chain that wraps around the pipe. This design provides a powerful grip on large, rough, or irregularly shaped pipes that standard wrenches can’t handle. It’s often used in oil, gas, and heavy construction work. The chain mechanism offers excellent control and strength, even in tight or limited spaces.

How to Use a Pipe Wrench

- Choose the correct size of wrench for your pipe.

- Open the jaws using the adjusting nut to fit the pipe snugly.

- Position the wrench so the teeth bite into the pipe surface.

- Apply steady pressure in the direction needed to turn the pipe.

- Avoid jerking movements to prevent damage.

- After use, clean the jaws and store the wrench in a dry place.

Advantages of Pipe Wrench

- Provides a firm grip on round pipes.

- Adjustable design fits various pipe sizes easily.

- Built to handle high pressure and heavy-duty tasks.

- Suitable for plumbing, gas, and mechanical applications.

Disadvantage of Pipe Wrench

- It can leave bite marks on soft or shiny pipes.

- Not designed for bolts or flat surfaces.

- Requires proper handling to avoid slippage.

- Heavier models can cause fatigue during long use.

Conclusion

Pipe wrenches are essential tools for plumbing and construction work, offering strength, durability, and precise control. Understanding the types of pipe wrenches and their uses helps you select the right one for every situation — from household repairs to large-scale industrial jobs. Whether you call it a pipe wrench or a plumbing wrench, this tool remains an unbeatable choice for gripping, turning, and securing pipes safely and efficiently.

FAQs

The three main types are straight pipe wrench, offset pipe wrench, and end pipe wrench.

It has a long handle with two serrated jaws that grip pipes securely, typically made from cast iron or aluminum.

A pipe wrench is also called a Stillson wrench, named after its inventor, Daniel Stillson.

The five key parts are a hook jaw, heel jaw, adjustable nut, spring assembly, and handle.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks