Different Types of Mechanical Seals

Published: 12 Oct 2025

Mechanical Seals are important for maintaining reliable, leak-free, and long-lasting industrial machinery. These seals serve as protective barriers, preventing fluid leakage and contamination between rotating shafts and stationary parts. Whether in pumps, compressors, or mixers, mechanical seals play a vital role in ensuring efficient performance and reducing maintenance downtime. In this article, we’ll discuss how they work, their key parts, functions, and various types used in industrial systems.

What Is a Mechanical Seal

A mechanical seal is a precision-engineered device that prevents leakage in rotating equipment by creating a secure interface between a stationary part and a rotating shaft. It is commonly used in pumps, compressors, and other systems that handle fluids or gases under pressure. Mechanical seals are essential in maintaining the internal environment of the equipment, ensuring energy efficiency, and avoiding costly downtime caused by leaks or contamination.

Mechanical Seal Parts

Mechanical seals have several important components that work together to maintain effective sealing:

Rotary Seal Ring: The rotating surface that makes contact with the stationary ring to form the sealing interface.

Stationary Seal Ring: Fixed against the equipment body to provide a stable sealing face.

Springs or Bellows: Maintain consistent pressure to keep the sealing surfaces in contact.

Secondary Seals (O-rings or Gaskets): Prevent leakage around other static areas.

Retainer and Gland Plate: Hold the seal assembly securely and ensure precise alignment.

How Does a Mechanical Seal Work

Mechanical seals work on the principle of two flat, smooth surfaces – one rotating and one stationary – pressed together under controlled pressure. A thin lubricating film forms between them, reducing friction and wear while preventing fluid from escaping. Springs or bellows maintain constant pressure on the sealing faces, compensating for wear, shaft movement, and vibration. This delicate balance between pressure, lubrication, and surface contact keeps the seal effective even under demanding operating conditions.

Types of Mechanical Seal

Mechanical seals are available in various configurations to suit different applications, environments, and fluid types. Below are the main types used across industries.

1. Single Spring Mechanical Seal

A single-spring mechanical seal utilizes one helical spring to press the sealing faces together, ensuring a tight seal. It’s simple in design and ideal for low to medium-speed operations. These seals are commonly used in domestic pumps, irrigation systems, and small industrial equipment. Their ease of maintenance and cost-effectiveness make them a popular choice for straightforward applications.

2. Multi-Spring Mechanical Seal

Multi-spring seals feature several small springs evenly distributed around the shaft, providing balanced pressure across the sealing faces. This design ensures uniform wear and reliable performance in high-speed and high-pressure operations. These seals are commonly found in oil refineries, chemical plants, and water treatment facilities where precision and durability are key. The compact design also allows for improved vibration control and longer service life.

3. Wave Spring Seals

Wave spring seals use a wave-shaped spring instead of conventional coil springs, allowing for compact installation in restricted spaces. These seals deliver consistent closing pressure and excellent performance in high-viscosity or high-speed systems. They’re ideal for pharmaceutical, food processing, and dairy applications where hygiene and precision are important. The design’s reduced spring height also minimizes friction and increases energy efficiency.

4. Rubber Bellow Seals

Rubber bellow seals use an elastomeric bellow element that provides flexibility and automatic adjustment for shaft misalignment. They are cost-effective and simple to install, making them suitable for light-duty pumps, domestic systems, and cooling water applications. These seals handle moderate temperatures and pressures effectively, offering a dependable solution for general industrial use.

5. Metal Bellow Seals

Metal bellow seals use corrugated metallic elements made from stainless steel or other alloys, providing excellent resistance to high temperatures and aggressive chemicals. They maintain constant face pressure even under fluctuating conditions, ensuring reliable sealing. These seals are commonly used in refineries, power plants, and chemical processing equipment where durability and long service life are essential.

6. PTFE Bellow Seals

PTFE (Teflon) bellow seals offer exceptional chemical resistance and are perfect for applications involving corrosive or hazardous substances. They can operate in extreme pH environments without degrading, making them a top choice for chemical and pharmaceutical industries. The non-stick property of PTFE also reduces friction, which helps minimize wear on the sealing surfaces and extends service life.

7. Mechanical Oil Seal

Mechanical oil seals are designed to retain lubricants and prevent contaminants from entering rotating machinery. They are commonly found in automotive engines, turbines, and gearboxes, ensuring smooth performance and minimal friction. The elastomeric lips of these seals provide tight sealing, while their metal casing adds rigidity and precise fitment. They help protect bearings and shafts from premature wear.

8. Shaft Seal Types

Shaft seals maintain pressure and prevent fluid leakage along rotating shafts in pumps and compressors. Depending on application needs, they can feature spring-loaded, bellow-style, or cartridge-type designs. Their versatility allows them to handle different fluids, temperatures, and shaft speeds. Properly selected shaft seals ensure long-term reliability and reduced maintenance requirements.

9. Conical Spring Mechanical Seal

Conical spring mechanical seals incorporate cone-shaped springs that automatically adjust to face wear and shaft misalignment. Their design provides self-cleaning action, reducing clogging and ensuring consistent sealing performance. These seals are robust, easy to assemble, and available for both clockwise and counterclockwise rotation. They’re widely used in wastewater, pulp, and paper industries.

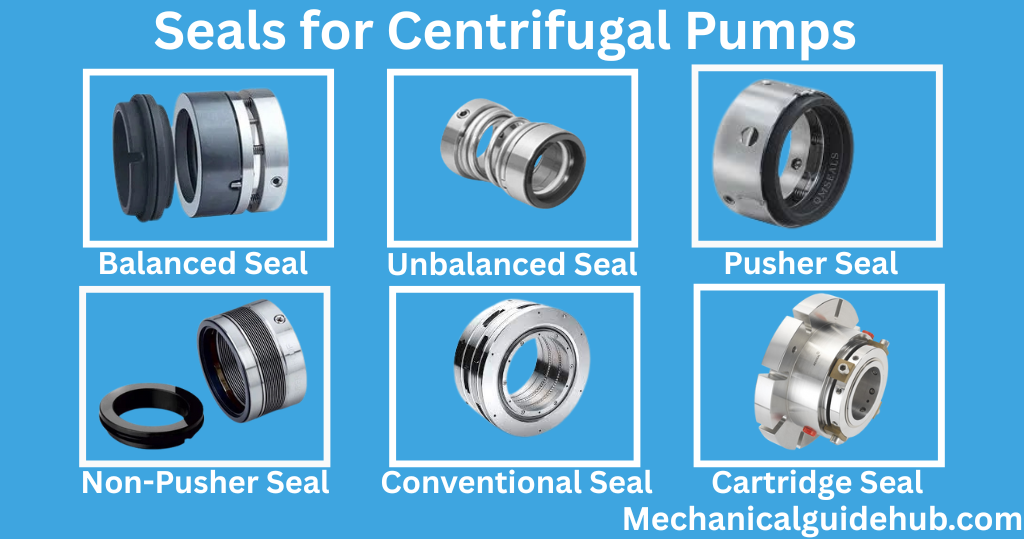

Types of Mechanical Seals for Centrifugal Pumps

Centrifugal pumps require specialized seals that handle high pressure, temperature variations, and fluid properties. Below are the main types designed for these pumps.

1. Balanced Seals

Balanced seals reduce face loading and heat generation by evenly distributing hydraulic forces across the sealing faces. This design ensures better lubrication and longer seal life, even at high pressures. They are ideal for applications involving low-lubricity or high-volatility fluids. Balanced seals are often used in boiler feed systems and chemical pumps where performance consistency is vital.

2. Unbalanced Seals

Unbalanced seals are simple in design and best suited for low-pressure systems, typically operating below 200 PSIG. They provide effective sealing at minimal cost and are less complex to install. While they may wear faster in high-pressure conditions, they offer tight face control and minimal leakage. These seals are common in water and HVAC applications.

3. Pusher Seals

Pusher seals utilize one or multiple springs to maintain face pressure as the shaft moves axially. They can handle high pressures but require careful maintenance because the O-ring may wear over time. These seals are cost-effective and widely used in high-speed pumps and compressors. Their versatility makes them a popular option for a variety of fluid types.

4. Non-Pusher Seals

Non-pusher seals rely on flexible metal or elastomeric bellows to maintain the sealing force instead of O-rings. They perform exceptionally well in high-temperature and contaminated fluid environments. Since there’s no sliding O-ring, they resist clogging and chemical degradation. These seals are perfect for handling viscous, abrasive, or corrosive fluids.

5. Conventional Seals

Conventional mechanical seals are installed directly into a pump’s stuffing box as separate components. While they are affordable and effective, they require skilled installation and alignment to function properly. These seals are commonly used in general-purpose pumps and equipment with moderate pressure ratings. Their modular design allows for easy customization.

6. Cartridge Seals

Cartridge seals are pre-assembled and pre-set units that simplify installation and minimize assembly errors. They come as complete, ready-to-install systems that save time and reduce the chance of leakage. These seals are ideal for high-performance industrial pumps where reliability and fast maintenance are essential. Their design ensures consistent face loading and extended operational life.

What Is the Function of Mechanical Seal

The primary function of a mechanical seal is to prevent fluid or gas from leaking while allowing the rotating shaft to pass through the pump housing. It ensures the internal system remains pressurized and uncontaminated. By minimizing leakage, it also protects equipment components from wear and extends overall service life.

Mechanical Seal Applications

Mechanical seals are used across a broad range of industries, including:

- Water treatment and wastewater systems

- Chemical and petrochemical processing plants

- Oil and gas refineries

- Power generation and HVAC systems

- Food and pharmaceutical production lines

Advantages of Mechanical Seal

- Superior leakage prevention compared to packing seals.

- Longer operational life and lower maintenance costs.

- Capable of withstanding high pressures and temperatures.

- Reduced friction, wear, and environmental contamination.

Disadvantages of a Mechanical Seal

- Higher initial cost compared to traditional packing seals.

- Requires precise installation and alignment.

- Sensitive to dry running and lubrication loss.

Conclusion

In conclusion, understanding the different types of mechanical seals is essential for choosing the right sealing solution for pumps and rotating machinery. Each seal type, whether single spring, bellows, or cartridge, offers distinct benefits tailored to specific operating pressures, temperatures, and fluids. Selecting the appropriate mechanical seal ensures system integrity, boosts efficiency, and enhances equipment longevity, making it a cornerstone of reliable industrial operation.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks