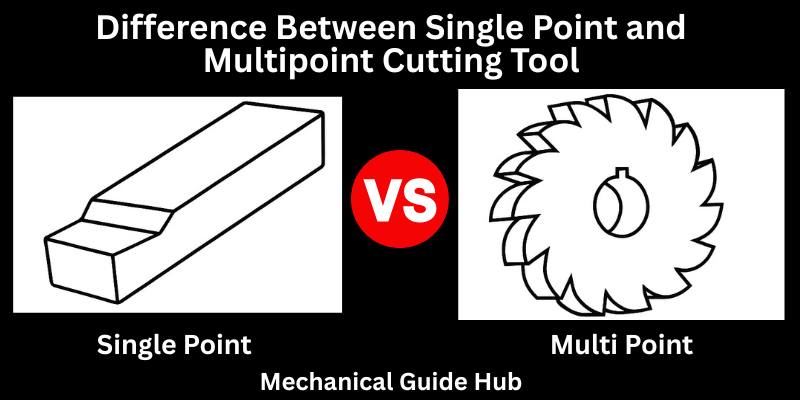

Difference Between Single Point and Multipoint Cutting Tool

Published: 5 Jul 2025

Cutting tools are used in machines to shape, trim, or remove extra material from workpieces like metal, wood, or plastic. These cutting tools are grouped into two types—single-point and multi-point cutting tools—based on the number of cutting edges they have. Let’s explore all possible differences between them in a clear and easy way, including some advanced but simple-to-understand ideas.

Single Point Cutting Tool

- It has only one main edge that performs all the cutting work. Even if the tool has more edges, only one is used at a time.

- It has one edge to remove the full amount of material, so it works harder.

- It is used on lathes, shapers, slotters, boring machines, and fly-cutting machines.

- The cutting edge remains in constant contact with the workpiece during cutting.

- One edge bears the full chip load, increasing cutting pressure and tool wear.

- Generates more heat in one area, which may cause tool damage or faster wear.

- Works at low speeds to reduce heat and protect the tool edge.

- Lower feed rates and a deeper cut are needed to avoid tool failure.

- Lower MRR—cuts slowly and removes less material at a time.

- Leaves a fairly smooth surface, but may need finishing.

- Wears out quickly because one edge does all the work.

- If the edge breaks, the whole process must stop, and the tool must be changed.

- May cause more vibration, especially in tough materials.

- Simple to sharpen and easy to reuse.

- It is easy to design, shape, and manufacture.

- Less expensive both to buy and to maintain.

- Best for roughing or shaping, where speed isn’t a big concern.

- Form long chips, which may be hard to remove.

- Not ideal for cutting extremely hard materials.

- E.g., shaping tool, fly cutter, turning tool, etc.

Multi-Point Cutting Tool

- It has two or more cutting edges. All cutting edges contact the workpiece simultaneously. Some tools may have dozens or even hundreds of edges, like grinding wheels.

- The material is shared among all edges, so each one removes less, reducing stress on each edge.

- It is used in drilling, milling, grinding, broaching, reaming, and hobbing machines.

- Edges engage and disengage often. This allows heat to escape, but may also cause vibration.

- The total cutting load is shared by all edges, which reduces pressure on each one and increases the tool’s lifespan.

- Heat is spread out, and edges cool when they disengage from the material.

- Can run at higher speeds, since the edges don’t stay in contact continuously.

- High feed and depth of cut are possible, which helps with fast cutting.

- Increase Material Removal Rate (MRR) by removing more material in less time through high-speed cutting.

- It gives a clean, polished surface in most cases.

- Lasts longer since the work is shared among many edges.

- If one edge breaks, others can still work, so the job may continue for a while.

- Usually more stable, but sometimes vibration occurs due to edge entry/exit.

- More difficult to sharpen, needs proper tools and care.

- It is complex to design and takes more time and skill to make.

- More expensive, but gives higher performance and speed.

- Perfect for high-speed machining and precision finishing across various industries.

- Form short chips, which are easy to handle and remove.

- Works better on hard materials due to a shared cutting load.

- Examples include drill bits, milling cutters, grinding wheels, broaches, and more.

Conclusion

If your job needs slow, careful shaping at a low cost, a single-point tool is the better choice. But if you need fast cutting, smoother surfaces, and longer tool life, go with a multi-point tool. Knowing the differences helps you pick the right tool and get the best results in your workshop or factory.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks