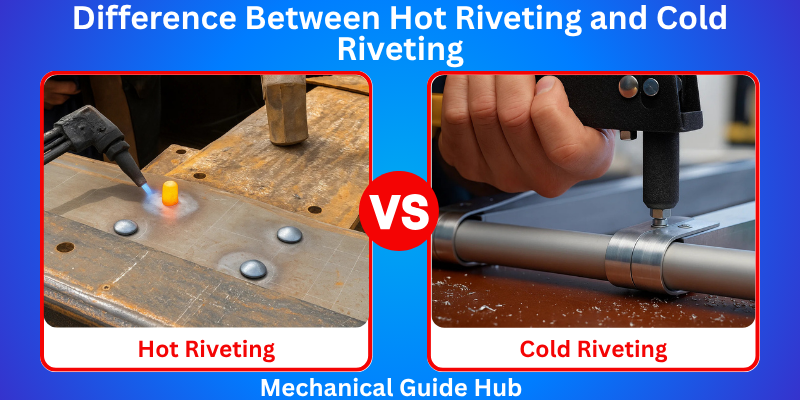

Difference Between Hot Riveting and Cold Riveting

Published: 1 Aug 2025

Riveting is a trusted method used to permanently join two or more materials, especially metal parts, in many structural and industrial applications. Among the different techniques available, hot riveting and cold riveting are the two most commonly used. In this article, we’ll explore the Difference Between Hot Riveting and Cold Riveting in a simple, clear, and easy-to-understand way.

Hot Riveting vs Cold Riveting: What’s the Difference?

| Comparison | Hot Riveting | Cold Riveting |

| Heat Usage | Before installation, the rivet is heated to a red-hot state, typically reaching 50% to 70% of its melting point. | The entire process is done without applying heat, keeping the rivet at room temperature. |

| Material Softness | Heat softens the rivets. This makes it easier to deform and shape during installation. | The rivet stays hard. More force is needed to shape it. |

| Tools and Equipment | The rivet must be heated in advance using an external source such as a furnace or torch. | Needs only hand tools or a rivet gun. No heating tools are required. |

| Force Required | Needs less hammering force. Hot metal is easier to shape. | Requires a higher force to deform the cold, hard rivet. |

| Time and Speed | Heating takes extra time and delays installation. | No heating means quicker work. |

| Grip Strength | The joint tightens naturally as the heated rivet cools. | The holding strength depends on the applied force and is generally not as tight as hot riveting. |

| Strength and Durability | Stronger joints. Ideal for heavy-duty and long-lasting structures. | Good strength for small or light-duty work, but not as durable under stress. |

| Rivet Size | Suitable for large rivets (over 10 mm). Easy to work with when hot. | Best for small rivets (under 10 mm). Larger ones are hard to shape without heat. |

| Vibration Resistance | Handles vibration better. The tight fit reduces joint movement. | Less effective against vibration. May loosen over time. |

| Appearance of Joint | Creates a clean, flush finish after cooling and shrinking. | Hard hammering can leave visible marks on the surface. |

| Safety | Higher risk of burns. Workers must wear heat-resistant gear. | Safer. No heat means fewer hazards on-site. |

| Skill Level Required | Needs skilled labor to handle heat and install rivets properly. | Easy to learn and perform with basic training. |

| Noise Level | Slightly quieter due to soft metal during hammering. | Louder. On impact, the hard metal produces more noise. |

| Energy Consumption | Uses more energy to heat the rivets. | Energy-efficient. Only needs mechanical force. |

| Portability | Less portable due to the heating equipment. | Portable. Can be done on-site with handheld tools. |

| Environmental Conditions | Not ideal for tight spaces or areas where open flames are unsafe. | Better suited for indoor or confined areas where heat is a risk. |

| Joint Type | Creates leakproof joints. Great for pressure vessels or tanks. | Not leak-proof. Suitable for dry or low-pressure joints. |

| Maintenance Needs | Last longer with fewer adjustments. | It may need tightening if the joint loosens over time. |

| Applications | Used in heavy structures like bridges, railways, boilers, and shipbuilding. | Common in electronics, tools, sheet metal, and light assemblies. |

Conclusion

Hot riveting and cold riveting serve the same purpose—joining materials—but in very different ways. Hot riveting uses heat, offers tight and durable joints, and is ideal for large jobs. Cold riveting is quick, safe, and suitable for small or delicate work. By understanding the full difference between hot riveting and cold riveting, you can make the right choice for strength, speed, and safety.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks