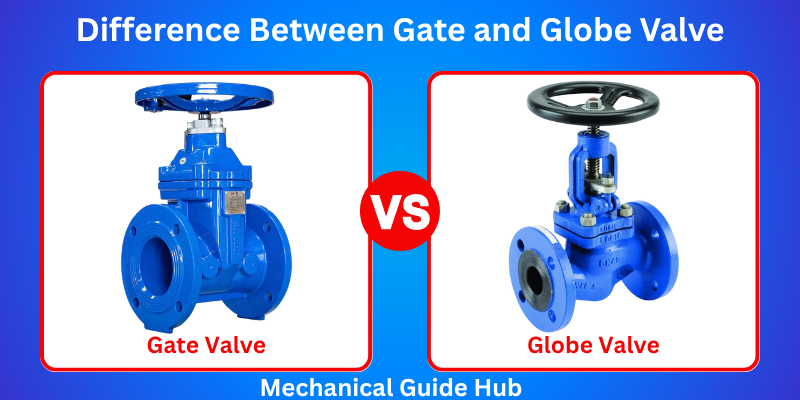

Difference Between Gate and Globe Valve

Published: 14 Jul 2025

Understanding the difference between gate and globe valves is crucial for selecting the right valve for the job. Although both are used to control fluid flow, they operate differently, have distinct designs, and are employed in various situations.

What is a gate valve

A gate valve uses a wedge-shaped disc that moves up or down to start or stop the flow.

When it’s open, fluid flows straight through without much resistance. That means there’s very little pressure drop, making it perfect for clean or thick fluids. But gate valves aren’t meant to control or adjust the flow—they’re best used in fully open or fully closed positions.

What is a globe valve

A globe valve, as the name suggests, has a round-shaped body and a plug-like disc. The disc moves up and down to adjust how much fluid passes through. This makes it great for controlling or throttling flow. Globe valves reduce pressure more than gate valves since the flow changes direction inside.

Gate valve

- A gate valve is great when you need a simple on/off function—no flow or full flow.

- Gate valves have a straight path inside. Flow moves in a straight line.

- Gate valves give fast flow with little pressure loss.

- Gate valves need more turns to open or close.

- Gate valves are budget-friendly and last long when used right.

- Gate valves work in both directions.

- Gate valves need extra vertical space because the stem moves upward.

- Gate valves seal well, but dirt or slight openings can reduce their sealing performance.

Common Applications

- Water distribution systems

- Irrigation pipes

- Underground pipelines

- Fire protection systems

- Slurry or wastewater lines

- Large tanks and storage systems

Globe Valve

- A globe valve is perfect for flow regulation. You can adjust it to low, medium, or high flow.

- Globe valves turn the flow inside with their curved body.

- Globe valves slow the flow and reduce pressure. This helps protect pipes.

- Globe valves are easy to use and quick to adjust.

- Globe valves cost more but offer better control. They may need more cleaning.

- Globe valves work in one direction only.

- Globe valves need more horizontal space but are shorter in height.

- Globe valves offer tight sealing under high pressure, making them ideal for leak prevention in safety systems.

Common Applications

- Water heaters and boilers

- Cooling systems and chillers

- Steam pipelines

- Chemical dosing systems

- Fuel oil lines

- Garden taps or hose bibs

Conclusion

While both gate and globe valves are essential tools in fluid systems, they serve different purposes. Use a gate valve when you want simple flow control without spending much. Pick a globe valve when precise flow control, safety, or pressure regulation is important. Making the right choice helps your system run more smoothly and efficiently.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks