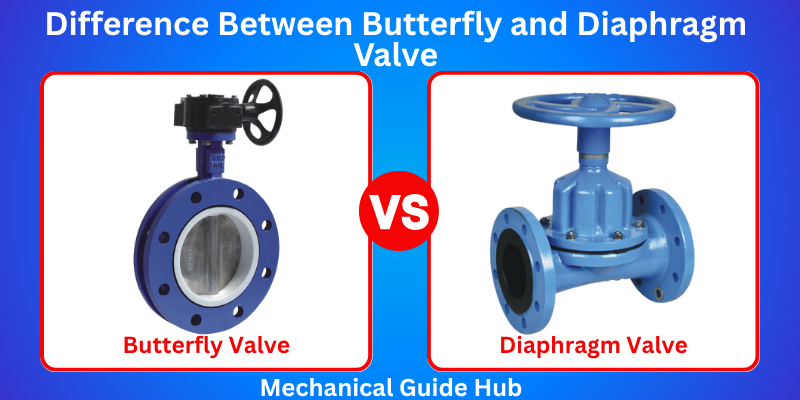

Difference Between Butterfly Valve and Diaphragm Valve

Published: 27 Jul 2025

Understanding the difference between butterfly valve and diaphragm valve is key when selecting the right valve for your project. Both are quarter-turn valves, but they vary significantly in how they operate, seal, and perform in different conditions. From water systems to pharmaceutical setups, knowing these differences can save time, money, and effort. This article highlights their unique features to help you make a confident decision.

Butterfly Valve vs Diaphragm Valve: Key Differences

| Parameters | Butterfly Valve | Diaphragm Valve |

| Design Structure | It has a circular disc on a rotating shaft that turns to open or close the flow. | A diaphragm valve uses a flexible diaphragm that moves up and down to control fluid flow. |

| Opening Mechanism | The disc rotates 90 degrees for opening or closing. | The diaphragm moves downward to seal the valve and stop flow. |

| Type of Movement | Quarter-turn valve (90-degree rotation). | Linear motion valve (up and down movement). |

| Sealing Method | It seals with an internal disc, though high pressure can cause slight leaks. | By pressing against the valve seat, the diaphragm offers leak-proof sealing. |

| Flow Control Precision | Works well for on/off and general throttling, but lacks precision. | Offers excellent throttling and precise flow control, making it suitable for sensitive operations. |

| Leakage Control | Suitable for basic use, not for ultra-clean or harmful fluids. | Excellent for leak-free and contamination-free processes. |

| Suitability | Not ideal for slurries or viscous fluids. | Works efficiently with dense, corrosive, or abrasive liquids. |

| Automation and Actuation | Easily automated with electric or pneumatic actuators. | Also compatible with actuators, but requires a more precise setup. |

| Installation Orientation | It can be installed horizontally or vertically. | Usually installed in an upright position for smooth diaphragm operation. |

| Operating Pressure | Works well under medium to high pressure, but can lose sealing ability. | Maintains a tight seal in low-pressure environments. |

| Service Life | Long-lasting under normal conditions, but may wear faster in harsh environments. | Durable in clean or corrosive systems, but diaphragms wear out over time. |

| Speed of Operation | Opens and closes quickly with a simple quarter turn. | Slower operation due to linear motion. |

| Size Availability | Widely available in many sizes, with a focus on larger diameters. | Typically used in small to medium-sized pipelines. |

| Weight and Space | Lightweight and compact, it saves space in piping systems. | Larger in size because of the top-mounted actuator and internal parts. |

| Cost | More cost-effective due to its simpler design and low manufacturing cost. | Costs more due to premium materials and design. |

| Applications | Ideal for use in heating systems, water processing, and various industrial pipelines. | Preferred in pharmaceuticals, food processing, chemical handling, and clean-room environments. |

Conclusion

The butterfly and diaphragm valves have their strengths and are suited to different operational needs. Butterfly valves are an ideal choice for large-volume flow systems where space, cost, and quick operation matter. On the other hand, diaphragm valves are the go-to choice for applications that require high purity, tight sealing, and precise control, especially in the pharmaceutical, food, and chemical industries. When choosing between the two, always consider your application’s pressure, media, flow control needs, and maintenance preferences.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks