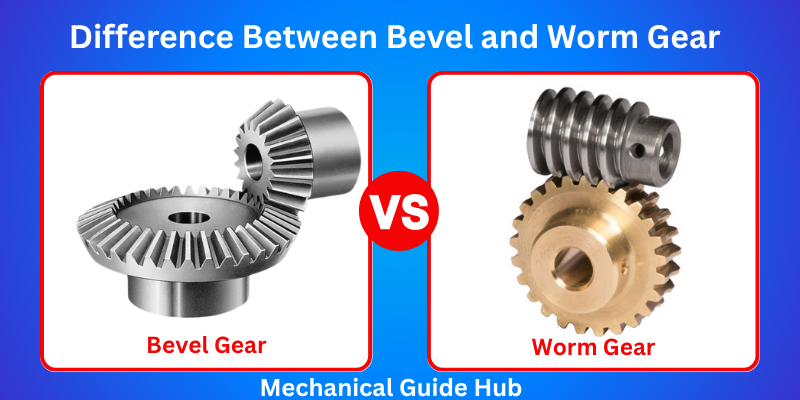

Difference Between Bevel and Worm Gear

Published: 28 Jul 2025

Understanding the difference between bevel and worm gear is essential when choosing the right gear system for your mechanical application. Both are used to transmit motion between non-parallel shafts, but their structure, performance, and ideal use cases vary greatly. Whether you’re working on a compact high-torque setup or need smooth, efficient power transfer, knowing how these gears differ can help you make a smarter, more efficient choice.

Bevel Gear vs Worm Gear: The Differences

| Parameters | Bevel Gear | Worm Gear |

| Design and Structure | A screw-shaped worm shaft connects with a worm wheel, forming a right-angle drive in a compact layout. | Made up of two conical gears with teeth cut on an angled surface, usually intersecting at 90 degrees. |

| Direction of Power Transmission | Transfers power between non-intersecting, perpendicular shafts, typically in only one direction. | Transfers power between intersecting shafts and can handle bi-directional motion. |

| Torque Transmission | Excellent at transmitting high torque in compact systems, though efficiency drops under heavy loads. | Handles moderate to high torque with less friction and smoother transmission. |

| Noise and Vibration | Typically noisier due to sliding contact, but can be quiet if precision-cut and well-lubricated. | Operates more quietly and smoothly, especially when designed with spiral or helical teeth. |

| Mounting Orientation | Can be mounted in horizontal or vertical positions. The worm is always the driver. | More versatile in shaft orientation, allowing multiple angular connections. |

| Maintenance Needs | Requires frequent lubrication and may wear faster due to friction. | Requires regular inspection, but generally offers a longer lifespan due to improved efficiency and reduced friction. |

| Backlash Considerations | Usually has less backlash but may wear quickly under high loads. | Backlash can be more prominent and needs adjustment for precision applications. |

| Self-Locking Ability | Often self-locking, meaning the gear can’t drive the worm back. Ideal for enhancing safety in hoisting and lifting applications. | Does not have self-locking properties. Additional components are needed for locking mechanisms. |

| Gear Ratio and Speed Reduction | Offers high gear reduction in compact setups, making it ideal for low-speed applications. | Bevel gears offer moderate reduction and good efficiency, ideal for high-speed setups. |

| Cost | Generally more affordable and compact, but may have higher long-term maintenance costs. | More expensive upfront due to complex manufacturing, but often lasts longer. |

| Applications | Found in elevators, hoists, gates, tuning instruments, conveyor systems, and heavy machinery, needing self-locking and compact design. | Common in automotive differentials, printing presses, hand drills, helicopters, and rotary tools, needing efficient torque at varying angles. |

Conclusion

In summary, the difference between bevel and worm gear comes down to their design, efficiency, torque handling, and application suitability. Worm gears are excellent for high torque and self-locking needs, while bevel gears shine in scenarios requiring efficient power transfer between intersecting shafts. Finding the right gear type hinges on how much space you have, what performance you need, and the gear ratio you’re aiming for.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks