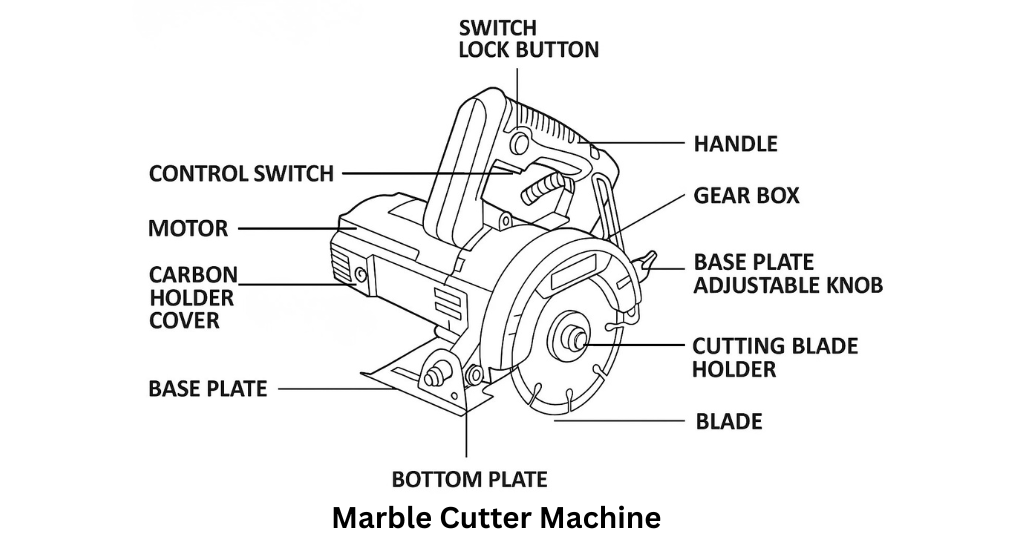

Marble Cutter Machine Parts Name and Their Function

Published: 14 Nov 2025

Marble cutting is an important task in construction and interior work. A marble cutter machine makes cutting marble and stone easier, faster, and more precise. In this article, we will discuss the Marble Cutter Machine Parts Name and Their Function. Each part of the machine plays a vital role in its performance. Understanding these parts helps operators work safely and achieve perfect cuts every time.

Marble Cutter Machine Parts Name and Their Function

A marble cutter machine has many parts, each performing a specific task. Knowing these parts helps operators handle the machine efficiently and safely. Let’s explore the main components and their functions.

1. Control Switch

The control switch is used to turn the machine on and off. It is easy to reach and allows the operator to start or stop the cutting process safely. Some machines have safety locks on the switch to prevent accidental operation.

2. Motor

The motor powers the cutting blade and provides the energy needed to cut through hard marble. A strong motor ensures fast and smooth cutting. The motor type also affects how efficiently the machine operates over long periods.

3. Carbon

Carbon brushes transfer electricity to the motor. They help maintain consistent power and smooth motor operation. Properly maintained carbon brushes ensure longer machine life and better performance.

4. Holder

The holder keeps the cutting blade firmly in place. It prevents the blade from wobbling or slipping during operation. This stability allows for more precise and safer cuts.

5. Cover

The cover protects the operator from dust, debris, and sparks produced during cutting. It also safeguards the machine’s internal parts from damage. A good cover improves safety and durability.

6. Base Plate

The base plate supports the machine on the marble surface. It provides stability and ensures straight, accurate cuts. A flat and strong base plate reduces vibration during operation.

7. Switch Lock Button

The switch lock button prevents the machine from starting accidentally. This safety feature is essential to protect both the operator and the workpiece. It allows controlled and secure operation.

8. Bottom Plate

The bottom plate gives extra support to the machine. It allows the cutter to glide smoothly on the marble surface. This part helps maintain even pressure and reduces uneven cuts.

9. Handle

The handle allows the operator to hold and maneuver the machine easily. Ergonomic handles reduce hand fatigue during long working hours. They also provide better control for precise cutting.

10. Gear Box

The gearbox carries power from the motor to the blade. It controls blade speed and ensures smooth rotation. A well-maintained gearbox increases cutting efficiency and machine longevity.

11. Base Plate Adjustable Knob

This knob adjusts the base plate’s height to achieve different cutting depths. It allows precise control when working on thick or thin marble pieces. Correct adjustment ensures cleaner and more accurate cuts.

12. Cutting Blade Holder

The cutting blade holder secures the cutting blade and keeps it aligned with the workpiece. It minimizes vibrations and ensures straight cuts. A good holder also improves operator safety during use.

13. Blade

The blade is the main cutting component of the machine. Diamond-tipped blades cut marble efficiently and produce smooth edges. Using the right blade type is key to fast, precise, and clean cuts.

Conclusion

A marble cutter machine has several important parts, and each contributes to safety, precision, and efficiency. From the motor and control switch to the blade and base plate, every component works together for smooth operation. This article will help operators achieve perfect marble cuts and prolong the life of the machine.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks