Forklift Parts Names and Their Functions

Published: 7 Oct 2025

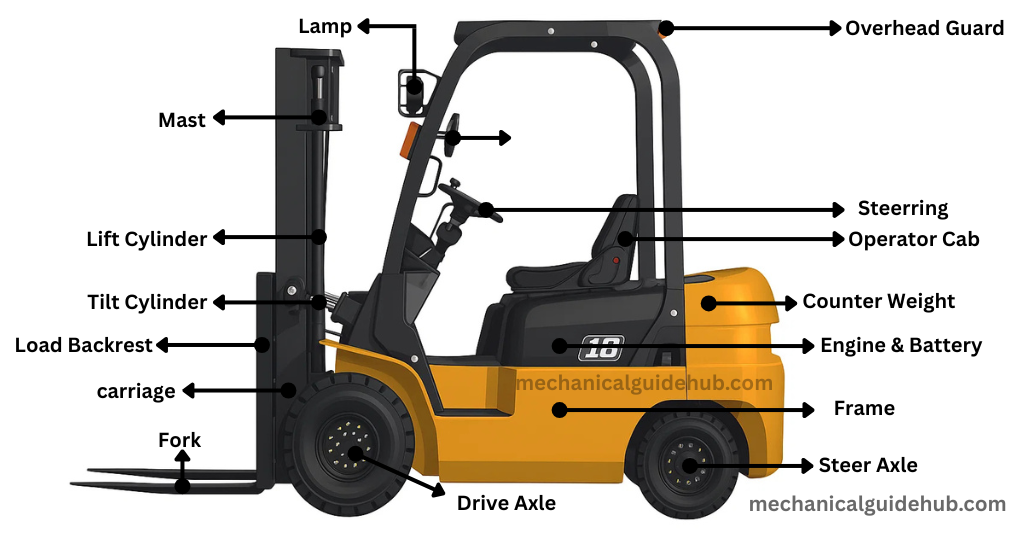

Forklifts play a vital role in industries like warehouses, factories, and construction sites. They help lift, move, and stack heavy materials efficiently. To ensure smooth and safe operation, it’s important to understand the forklift parts name and their functions. Each component works together to provide stability, power, and control. Let’s explore the main forklift parts that make these powerful machines work so effectively.

Forklift Parts Name and Their Functions

1. Mast

The mast is the tall, vertical assembly at the front of the forklift. It lifts and lowers loads using hydraulic power. It ensures the smooth and controlled raising of heavy items. Regular lubrication keeps the mast functioning efficiently and safely.

2. Carriage

The carriage sits on the mast and holds the forks. It moves up and down as the load is lifted or lowered. It provides stability to the load and allows attachments like clamps or extensions to be fitted easily.

3. Forks (Tines)

Forks are the metal arms that carry the load. They slide under pallets or materials for lifting and transport. Made of durable steel, forks come in various sizes and must be inspected regularly to avoid bending or cracking.

4. Counterweight

Located at the rear of the forklift, the counterweight keeps the vehicle balanced during lifting. It prevents the forklift from tipping forward when carrying heavy loads. The right counterweight is crucial for safety and stability.

5. Overhead Guard

The overhead guard is a protective frame above the operator’s seat. It shields the operator from falling objects or debris while loading and unloading. Although strong, it should be checked for any damage to maintain safety.

6. Load Backrest

The load backrest is attached to the carriage, preventing the load from falling backward toward the operator. It provides extra support for tall or unevenly stacked items.

7. Hydraulic Pump

The hydraulic pump is responsible for lifting and tilting actions. It pushes hydraulic fluid into the cylinders to raise or lower the mast and forks. Smooth hydraulic performance ensures precise load control.

8. Lift Cylinder

Lift cylinders are part of the hydraulic system that moves the mast up and down. They allow the forklift to handle heavy loads effortlessly. Keeping them free from leaks ensures efficient operation.

9. Tilt Cylinder

The tilt cylinders control the forward and backward tilt of the mast. This feature helps secure loads and prevents them from slipping during lifting or stacking.

10. Drive Axle

The drive axle transfers power from the engine or motor to the wheels. It helps the forklift move forward and backward smoothly. Proper lubrication of the axle reduces wear and tear.

11. Steering Axle

The steering axle controls the turning of the forklift. Rear-wheel steering allows easy movement in tight spaces, making it ideal for warehouses.

12. Power Source

Forklifts can be powered by internal combustion engines or electric motors.

Internal combustion engine: Uses diesel, petrol, or LPG fuel.

Electric Motor: Runs on a rechargeable battery, offering quiet and eco-friendly operation.

13. Transmission

The transmission controls the forklift’s speed and direction. It works with the engine or motor to deliver smooth motion. Regular fluid checks help maintain its performance.

14. Wheels and Tires

Forklifts use either pneumatic or solid tires depending on the surface. Pneumatic tires are air-filled for outdoor use, while solid tires are ideal for smooth indoor floors.

15. Operator Cab

The operator’s cabin is where the driver sits and controls the forklift. It includes a steering wheel, pedals, levers, and display panels. A comfortable and safe cabin design improves operator performance.

16. Seat Belt

The seat belt secures the operator in place and prevents injury during sudden stops or uneven movements. It’s a simple yet essential safety feature.

17. Safety Lights and Horns

Lights and horns alert nearby workers when the forklift is moving. These features are vital in busy industrial areas for preventing accidents.

18. Battery (for Electric Forklifts)

Electric forklifts use a rechargeable battery as their main power source. Proper maintenance, including regular charging and cleaning of terminals, extends battery life and ensures consistent performance.

19. Lifting Chain

The lifting chain connects the mast and carriage, enabling smooth vertical movement. It needs regular inspection to avoid wear or breakage during operation.

20. Nameplate

The nameplate displays important details such as load capacity, model number, and lifting height. It’s an essential reference for safe operation.

Conclusion

A forklift’s efficiency and safety depend on the condition of its parts. Knowing the forklift parts name and their functions helps operators use the machine more effectively and perform proper maintenance. From the mast that lifts loads to the counterweight that keeps it balanced, each part plays a key role in daily operations. Regular servicing and inspections not only improve performance but also extend the forklift’s lifespan. A well-maintained forklift means a safer, faster, and more productive work environment.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks