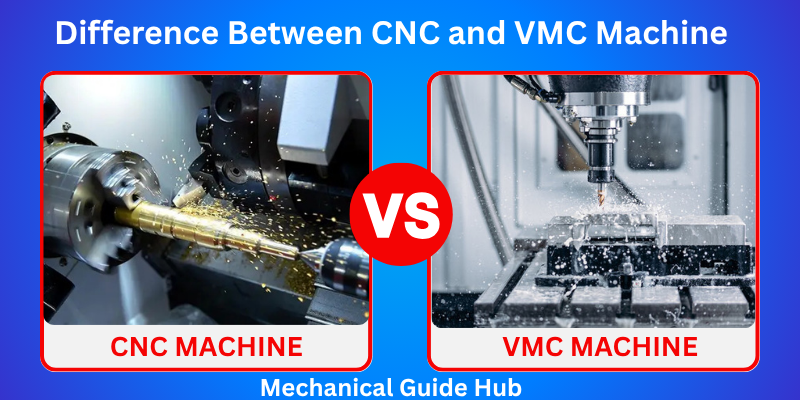

Difference Between CNC and VMC Machine

Published: 24 Jul 2025

In today’s advanced manufacturing landscape, machines drive precision, efficiency, and productivity. CNC and VMC machines are crucial to automation, yet many people confuse them because of their similar roles. Understanding the differences between CNC and VMC machines is essential for choosing the right equipment. Let’s explore how they differ in structure, operation, and usage.

CNC vs. VMC Machine Differences

CNC Machine

- CNC (Computer Numerical Control) machines operate using pre-programmed G-code to automate machining tasks with precision.

- They perform high-accuracy operations such as cutting, drilling, grinding, and turning through computer-controlled tool movement.

- Can be horizontal, vertical, or even multi-axis depending on the machine type.

- The tool or workpiece may rotate depending on machine type.

- May require manual or semi-automatic tool change.

- High precision, but varies based on machine type.

- Both use G-code and M-code for programming.

- Extremely versatile. One system can manage lathes, routers, grinders, etc.

- Uses a turret to hold tools.

- Works with metals, plastics, wood, composites.

- Range from simple to extremely complex multi-axis tasks.

- Requires trained personnel for multi-purpose operations.

- More economical, especially when used for basic turning and small-scale manufacturing.

- Widely used in automotive, aerospace, and metalworking for turning, threading, and boring.

VMC Machine

- VMC stands for Vertical Machining Center. It is a specific type of CNC machine with a vertically oriented spindle.

- It is primarily used for milling tasks, offering high precision and efficiency in vertical machining operations.

- Always vertical spindle orientation; typically 3 to 5 axes (X, Y, Z, plus rotational axes A & B).

- The tool moves; the workpiece does not.

- Equipped with ATC (Automatic Tool Changer) for faster operations.

- Very high accuracy, especially in intricate milling tasks, mold-making, and die-cutting.

- VMC programming often includes advanced tool path strategies for milling operations.

- More specialized but limited to vertical tasks.

- Designed with a magazine and spindle for hassle-free automatic tool changes.

- Best suited to hard materials like aluminum, steel, titanium, but can also cut plastics and composites.

- Performs exceptionally well in machining detailed 2D and 3D surfaces.

- Easy to manage for specific milling functions; less operator fatigue due to automation.

- Usually more expensive due to complex structure, multi-axis control, and higher tooling needs.

- VMC machines excel in milling applications across the mold making, electronics, and aerospace sectors.

Conclusion

To wrap it up, while a VMC is a type of CNC machine, the distinction lies in their structure and purpose. CNC machines are the broader category, often used for turning, while VMCs specialize in vertical milling with precise multi-axis operations. Choosing the right machine depends on your specific manufacturing needs. Use a VMC for shaping complex parts and a CNC lathe for turning cylindrical components. Understanding the differences between CNC and VMC machines helps ensure you select the right tool for high-quality results.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks