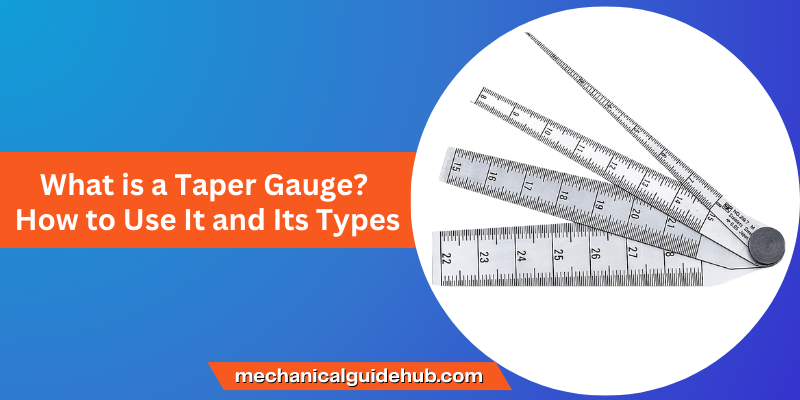

What is a Taper Gauge? How to Use It and Its Types

Published: 7 Jul 2025

Let’s talk about taper gauges. These small tools may look simple, but they do an important job. In this post, we’ll explain what a taper gauge is, the different types, how to use one, and where it’s used.

What is a Taper Gauge?

A taper gauge is a tool used to measure gaps, inside tapers, outside tapers, holes, grooves, or other small spaces. It checks how wide or narrow the space is. The gauge has a thin, flat, and pointed shape that gradually gets wider from one end to the other. The size is marked on the so you can read the measurement easily. It’s fast, simple, and useful for checking tight spaces.

Types of Taper Gauge

There are many types of taper gauges. Each type works for a special job.

1. Taper Plug Gauge

It Used to measure internal tapered holes or bores.

It looks like a small, tapered pin. You insert it into the hole. If it fits within the marked limits (GO and NO-GO), the hole size and taper angle are correct.

Taper Plug Gauge Used for

- Checking tapered internal parts

- Ensuring the taper is within tolerance

- Common in machining and pipe fitting

Taper Ring Gauge

A taper ring gauge is used to check the outside of a part, like a shaft or rod, that has a taper.

It looks like a ring with a taper inside. You slide it over the part. If it fits correctly, the outer taper is accurate.

Taper Gauge Used for

- Checking tapered external parts

- Quick fit check for shafts and spindles

- Often used in manufacturing and inspection

How to Use Taper Gauge

Here’s how to use a taper gauge:

- Place the tapered blade into the gap or hole.

- Slide it gently until it fits well.

- Check the size shown on the scale or screen.

- Make sure the surface is clean for better accuracy.

Taper Gauge Uses

You’ll find taper gauges in many places:

- In workshops to measure gaps or holes

- In welding, to check the joint fit

- In quality control, to inspect parts

- In pipe fitting to match taper threads

They are handy tools for anyone working with machines or metal parts.

Conclusion

Taper gauges are easy to use and give quick, accurate results. Whether you’re checking gaps, holes, or threads, there’s a type that fits your needs. Pick the right gauge and follow simple steps—you’ll get the job done right every time.

FAQs

Checks the taper inside holes or bores. It also makes sure the angle and depth are within limits.

A basic taper gauge typically costs between $5 and $15. Digital or threaded types can cost more, depending on quality.

0.1 mm is the common least count of taper gauges.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks