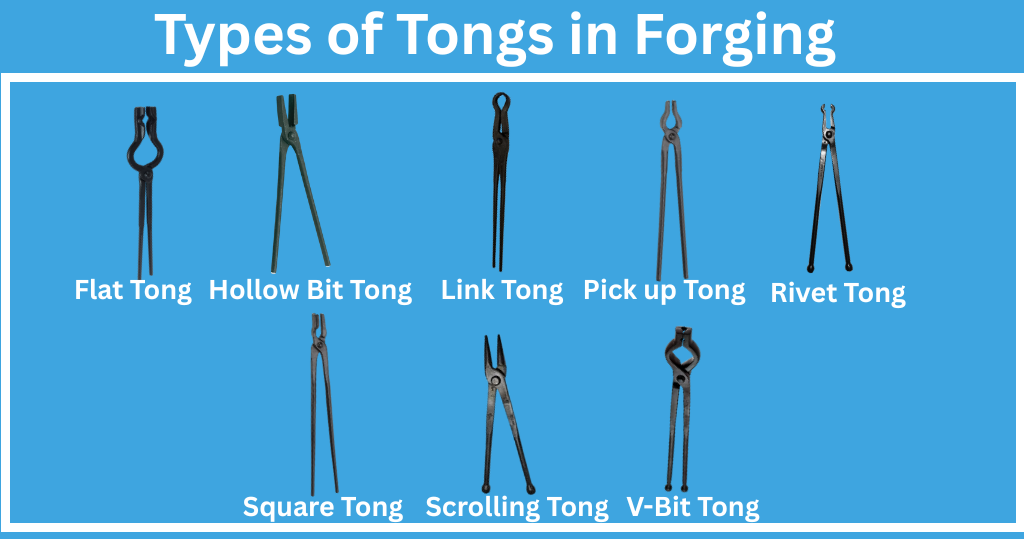

Different Types of Tongs in Forging

Published: 17 Oct 2025

Forging is a process where metal is shaped by heating and hammering. To hold and control the hot metal safely, blacksmiths use a special tool called a forging tong. These tongs come in different shapes and sizes, each designed for a specific job. Let’s explore the most common types of tongs used in forging and understand how they help with metalwork.

What is forging Tong?

A forging tong is a hand tool used by blacksmiths to grip and hold hot metal pieces while working. It provides a firm hold, keeping the smith safe from heat and sparks. Forging tongs are made of strong steel to handle high temperatures and heavy pressure. The right tong helps in better control and accuracy during the forging process.

Different Types of Tongs in Workshop

1. Flat Tong

Flat tongs are used to hold flat metal bars or sheets. They have broad, flat jaws that grip the workpiece tightly. These tongs are ideal for general forging tasks where a flat and even surface needs to be handled securely.

2. Hollow Bit Tong

Hollow bit tongs have curved jaws with a small hollow space. This shape helps in holding round or square bars firmly. They are perfect for working on pipes, rods, and other rounded materials that may slip with flat tongs.

3. Link Tong

Link tongs are designed with long jaws and strong handles. They are often used to hold chain links or ring-shaped pieces during forging. The design provides a deep and steady grip, preventing the workpiece from slipping while being hammered.

4. Pick Up Tong

Pick up tongs are simple and lightweight. They are used to move or pick up small hot pieces from the forge. These tongs are not meant for heavy forging but are very handy for quick handling and transferring of metal.

5. Rivet Tong

Rivet tongs are used for holding rivets or small, round metal pieces. Their narrow jaws fit perfectly around the rivet, making them useful for precise work like joining metal parts. They allow better control while hammering rivets into place.

6. Square Tong

Square tongs are made to hold square bars or rods securely. The jaws are shaped to match the corners of square workpieces, giving a tight grip without slipping. They are essential when working with square stock material.

7. Scrolling Tong

Scrolling tongs have narrow, pointed jaws that make them perfect for shaping and bending metal into curves or spirals. Blacksmiths use them for decorative and detailed metalwork, especially when making scrolls or ornamental designs.

8. V-Bit Tong

V-bit tongs have jaws shaped like a “V.” This design helps hold both round and square workpieces firmly. They are versatile and commonly used for general blacksmithing work because of their strong and balanced grip.

Conclusion

Choosing the right forging tong makes metalworking safer and easier. Each type of tong, from flat and hollow bit to V-bit and scrolling, serves a unique purpose. Knowing which one to use helps you handle hot metal with confidence and precision. Whether you’re a beginner or a skilled blacksmith, using the correct types of tongs in forging improves your craft and ensures better results every time.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks