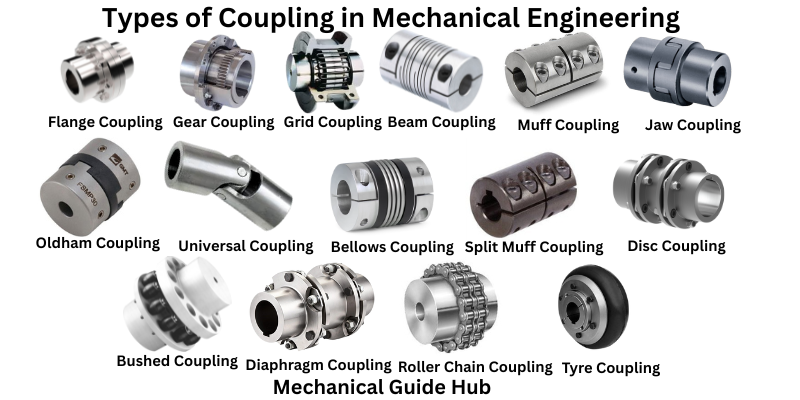

Types of Coupling in Mechanical Engineering

Published: 2 Oct 2025

Couplings are one of the most essential elements in mechanical engineering because they connect two shafts to transmit power efficiently. They not only provide smooth torque transfer but also reduce shocks, vibrations, and the effects of misalignment. By using the right coupling, machinery becomes more reliable, safe, and long-lasting. In this article, we’ll explain what shaft couplings are, the different types, their uses, and why they are important in modern engineering.

What is Shaft Coupling

A shaft coupling is a device used to connect two shafts together at their ends to transfer torque and motion. They are widely used in pumps, compressors, conveyors, automobiles, and industrial machines. A good coupling should transmit full power without losses, allow easy installation, reduce vibration, and compensate for slight misalignment between shafts.

In mechanical systems, couplings are mainly classified into rigid couplings and flexible couplings.

Rigid couplings are used where the shafts are perfectly aligned. They cannot handle misalignment but ensure accurate power transmission.

Flexible couplings can absorb shocks, vibrations, and allow angular or axial misalignment.

Additionally, there are fluid couplings, which use hydraulic action for smooth torque transfer in heavy-duty systems.

Types of Shaft Coupling

1. Shaft Coupling

The general term “shaft coupling” refers to devices that link two shafts for power transmission. They vary in size, material, and function depending on the torque, speed, and alignment required. Shaft couplings ensure efficiency and extend the life of both machinery and connected components.

2. Flange Couplings

Flange couplings consist of two flanges mounted at the ends of shafts. These flanges are bolted together, creating a rigid connection. They are reliable, durable, and commonly used in heavy-duty machines like marine engines, turbines, and pumps. However, they require perfect shaft alignment for proper operation.

3. Gear Couplings

Gear couplings use toothed hubs and sleeves to transmit torque between shafts. They can handle high torque loads and allow small amounts of angular and axial misalignment. Because of their strength, gear couplings are used in steel rolling mills, cranes, and other heavy-duty applications.

4. Grid Couplings

Grid couplings use a spring-like steel grid fitted into the grooves of flanged hubs. They provide flexibility by absorbing shock loads and vibrations. This makes them a preferred choice for industries such as paper manufacturing, conveyors, and compressors where smooth torque transmission is necessary.

5. Beam Coupling

Beam couplings are made from a single piece of metal cut in a helical pattern. This design provides flexibility for angular, axial, and parallel misalignment. They are lightweight, precise, and commonly used in automation, robotics, and instrumentation where accuracy is vital.

6. Sleeve or Muff Coupling

The sleeve or muff coupling is one of the simplest types of rigid coupling. It consists of a hollow sleeve that fits over the ends of two shafts with the help of a key. While inexpensive and compact, this type of coupling cannot absorb shocks or tolerate misalignment, making it suitable only for low-speed applications.

7. Jaw Couplings

Jaw couplings consist of two metal hubs with curved jaws and an elastomer insert between them. The Elastomer provides flexibility and dampens vibrations, ensuring smooth operation. Jaw couplings are commonly used in pumps, compressors, and small machinery due to their easy installation and low maintenance.

8. Oldham Coupling

Oldham couplings are designed to connect two parallel shafts with slight misalignment. They have two hubs with slots and a central disc that slides between them, allowing torque transfer. These couplings are often used in printing machines, packaging equipment, and other light-duty applications.

9. Universal Coupling

Also known as Hooke’s joint, the universal coupling connects shafts that are at an angle to each other. It allows torque transmission even when the shafts are not collinear. Universal couplings are widely used in automobiles, especially in drive shafts, as well as in aircraft and industrial equipment.

10. Bellows Coupling

Bellows couplings are made of thin, corrugated metal that allows flexibility while maintaining torsional stiffness. They provide precise torque transmission with zero backlash, making them ideal for motion control systems, robotics, and measuring instruments.

11. Split Muff Coupling

Split muff couplings consist of a sleeve split into two halves, which are clamped together using bolts. They are easier to assemble and dismantle than sleeve couplings since shafts don’t need to be moved during installation. This makes them suitable for heavy-duty and medium-speed applications.

12. Disc Coupling

Disc couplings use a set of thin metal discs that flex under torque transmission, allowing for angular and axial misalignment. They are durable, lightweight, and designed for high-speed applications such as turbines, compressors, and precision machinery.

13. Bushed Coupling

Bushed pin couplings use rubber or leather bushes placed around the bolts or pins. These bushes provide cushioning, reducing vibration and noise during operation. Bushed couplings are widely used in automobiles and machines that need shock absorption.

14. Diaphragm Coupling

Diaphragm couplings transmit torque through a flexible metallic diaphragm. They are capable of handling high speeds and significant misalignment while maintaining strength and precision. These couplings are often used in power plants, turbines, and compressors.

15. Roller Chain Coupling

Roller chain couplings have two sprockets linked together with a roller chain. They are strong, easy to assemble, and capable of handling misalignments. Due to their rugged design, they are commonly used in conveyors, agricultural machinery, and heavy industrial equipment.

16. Tyre Couplings

Tyre couplings use a flexible rubber element shaped like a tyre. They are highly effective at absorbing shocks and vibrations while accommodating misalignment. These couplings are popular in pumps, compressors, and other machinery that requires durability and flexibility.

Applications of Shaft Coupling

Shaft couplings are used across many industries where power transmission between two shafts is required. Common applications include:

- Connecting electric motors to pumps, compressors, and generators.

- Transmitting power in automobiles between the gearbox and the differential.

- Heavy-duty industrial machines such as conveyors, turbines, and fans.

- Absorbing shock loads in machines like crushers, mixers, and blowers.

- Allow safe operation by disconnecting or acting as a weak link during overload.

Conclusion

Shaft couplings are small components with a big role in mechanical systems. From simple muff couplings to advanced diaphragm and tyre couplings, each type is designed for specific applications. Choosing the right coupling ensures smooth power transmission, reduces wear and tear, and extends machine life. Whether in cars, factories, or turbines, couplings remain the hidden heroes of mechanical engineering.

FAQs

There are mainly two broad categories: rigid and flexible. Within these, there are multiple types such as flange, gear, grid, jaw, Oldham, universal, disc, tyre, and more, making over a dozen common types.

No coupling is inherently the worst, but rigid couplings can be problematic if shafts are not properly aligned. They cannot tolerate misalignment, which can cause extra stress and damage.

Sleeve or muff couplings are often the least preferred in modern machines because they are rigid, cannot absorb shocks, and require precise alignment, which limits their use in advanced systems.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks