Screw Gauge: Parts, How to Use, and Formula

Published: 2 Oct 2025

What is Screw Gauge?

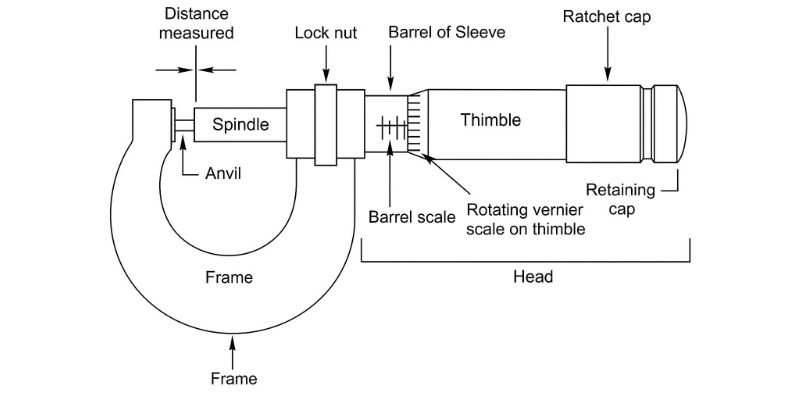

Screw Gauge Diagram

A screw gauge, also called a micrometer, is a device that measures tiny thicknesses or diameters of objects. It works using a finely threaded screw that moves the spindle forward or backward. This motion helps measure objects like wires, sheets, or small machine parts with incredible accuracy, often up to 0.01 mm.

Screw Gauge Parts

Frame: The solid C-shaped body that holds all parts together. It provides strength and stability during measurement.

Anvil: A fixed surface against which the object is placed. It works with the spindle to hold the object tightly.

Spindle: A movable screw that moves forward or backward. It touches the object for accurate measurement.

Sleeve (or Barrel): A fixed cylindrical part marked with a main scale. It helps in reading the main measurement.

Thimble: A rotating part attached to the spindle. It has a circular scale to measure small divisions.

Ratchet Stop: A small knob at the end of the thimble. It prevents extra force and ensures consistent pressure.

Lock Nut: A part used to lock the spindle in position. It holds the reading steady while checking or recording.

How to Use Screw Gauge

Using a screw gauge is simple:

- Clean the spindle and anvil.

- Place the object between the anvil and spindle.

- Turn the ratchet until you hear three clicks.

- Lock the spindle with the nut.

- Take the reading from the sleeve and thimble scales.

- Apply any zero-error correction if needed.

This process ensures accuracy in every measurement.

Screw Gauge Formula

The screw gauge works on two main parameters: pitch and least count. These formulas help in calculating the exact measurement of small objects.

- Pitch of Screw Gauge Formula

Pitch is the distance moved by the spindle in one complete rotation of the screw.

Pitch = Distance moved by screw / Number of rotations given

- Least Count of Screw Gauge Formula

Least Count is the minimum measurement a screw gauge can take, found by dividing the pitch by the total number of divisions on the circular scale.

Least Count (LC) = Pitch / Total divisions on circular scale

Advantages of Micrometer Screw Gauge

- Very high accuracy (up to 0.01 mm or better).

- Simple to operate after little practice.

- Sturdy and long-lasting.

- Different types available for inside, outside, and depth measurements.

- Ideal for industries requiring precision.

Disadvantages of Micrometer Screw Gauge

- Limited measuring range per instrument.

- Needs careful handling to maintain accuracy.

- Manual reading may lead to small human errors.

- Cannot measure large or irregular objects.

Uses of Micrometer Screw Gauge

- Measuring the diameter of wires and thin rods.

- Checking the thickness of small sheets or metal strips.

- Used in laboratories for physics experiments.

- Quality control in manufacturing industries.

- Precision work in mechanical workshops and toolmaking.

Conclusion

A screw gauge (micrometer) is a vital measuring instrument when precision matters. From its simple design to its ability to measure extremely small dimensions, it plays an important role in industries, labs, and workshops. By understanding its parts, formulas, and applications, one can use it effectively and ensure accurate results every time.

FAQs

The price varies depending on type and quality. A manual screw gauge usually costs $10 to $100, while digital versions can go higher.

It is a precision tool used to measure very small dimensions, such as wire diameter or sheet thickness, with high accuracy.

Most manual screw gauges have a least count of 0.01 mm, while advanced digital ones can measure up to 0.001 mm.

Since 0.01 mm = 0.001 cm, the least count of a screw gauge in centimeters is 0.001 cm.

Read the main scale (sleeve) value, add the thimble reading multiplied by the least count, and adjust for zero error if present.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks