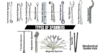

Sand Casting Tools and Equipment and Their Uses

Published: 24 Nov 2025

Sand casting is a simple and widely used metal casting method. It involves pouring molten metal into a sand mold to create metal parts. While the process seems simple, it requires various tools and equipment to ensure accuracy, efficiency, and safety. In this article, we will discuss the main sand casting tools and equipment used by professionals in foundries.

Sand Casting Tools and Equipment

The tools used in sand casting can broadly be classified into hand tools and mechanical aids. Hand tools are essential for mould preparation, pattern handling, and ensuring proper cavity formation. Mechanical aids help with efficiency and consistency, especially in mass production.

1. Slick

A slick is a flat, oval-shaped tool used for smoothing and finishing mould surfaces. One end is flat, and the other is shaped like a spoon for repairing curves and corners in the mould. Slicks are crucial for creating precise surface finishes and ensuring that the final casting is defect-free.

2. Shovel

The shovel is one of the primary tools in a foundry. It is used for transporting sand from the pile to the moulding flask and for mixing and tempering the sand by adding water. Its broad blade and long handle make it efficient at handling large quantities of sand.

3. Riddle

A riddle is a wire mesh fitted to a wooden or metal frame. It is used for sieving the sand to remove foreign particles like stones and nails. This ensures that the sand used in moulding is clean and uniform, which is essential for smooth casting surfaces.

4. Rammer

A rammer is employed to compact the sand around the pattern firmly. Usually made of hardwood or metal, it has a flat end for general ramming and a wedge-shaped end (peen) for detail areas. Proper ramming ensures the mould cavity retains its shape during metal pouring.

5. Lifter

The lifter is a tool made of mild steel, used to remove loose sand particles from the mould. It is also useful for repairing or finishing the mould cavity after the pattern has been withdrawn.

6. Swab

A swab is a soft brush with a rubber bulb used to moisten sand around the pattern’s edges. This prevents sand breakage during pattern removal and helps maintain the cavity shape.

7. Bellow

Bellows are used to blow off loose sand from the mould and pattern. This ensures a clean surface for pouring molten metal and prevents defects caused by stray sand particles.

8. Trowel

A trowel is a steel-bladed tool with a wooden handle, used to smooth, patch, and repair the flat surfaces of the mould. It comes in different shapes and sizes to suit various casting requirements.

9. Gate Cutter

The gate cutter is a U-shaped sheet metal tool used to cut gates and runners in the mould. These channels allow molten metal to flow into the cavity efficiently and are critical for controlling metal flow and solidification.

10. Strike Off Bar

A strike-off bar, made of wood or metal, is used to level excess sand in the mould after ramming. This ensures the mould surface is even and ready for further operation.

11. Vent Wire

The vent wire is a pointed steel rod used to make small holes in the sand mould. These vent holes allow gases to escape when molten metal is poured, preventing gas-related defects in castings.

12. Sprue Pin

A sprue pin is a tapered wooden peg used to create vertical passages in the cope section of the mould. These passages allow molten metal to enter the cavity. The pins used for risers are known as riser pins.

13. Sprue Cutter

A sprue cutter is used to shape and trim the sprue after it has been formed in the mould. It ensures smooth metal flow and easy removal of the sprue after casting.

14. Ladle

A ladle is a metal container used to collect and pour molten metal into a mould. It is coated with refractory material inside to withstand high temperatures and allow safe handling during pouring.

Conclusion

Sand casting may seem simple, but the quality of the final product depends heavily on the right tools and equipment. Using the correct tools ensures smooth metal flow, precise shapes, and defect-free castings. Whether you are a beginner or an experienced foundry worker, understanding these sand casting tools and equipment is essential for successful metal casting.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks