Lancashire Boiler Construction, Working and Applications

Published: 19 Oct 2025

The Lancashire Boiler is one of the most reliable and widely used fire tube boilers in industries. Known for its simple construction, high thermal efficiency, and ability to generate large amounts of steam, this boiler has been a staple in industrial applications since its invention by William Fairbairn in 1844. It operates on a natural circulation system and is designed for low-pressure steam generation, making it perfect for industries where steam is needed for processing and power generation.

What is Lancashire Boiler?

A Lancashire Boiler is a horizontal, stationary, low-pressure, internally fired fire tube boiler. Unlike the Cornish Boiler, which has a single fire tube, the Lancashire Boiler has two large fire tubes running through its cylindrical shell. The boiler works on the principle of heat exchange, where flue gases pass through the tubes and water surrounds the shell, transferring heat efficiently to produce steam.

This natural circulation boiler uses water current generated by temperature differences, eliminating the need for external pumps and making it economical and energy-efficient.

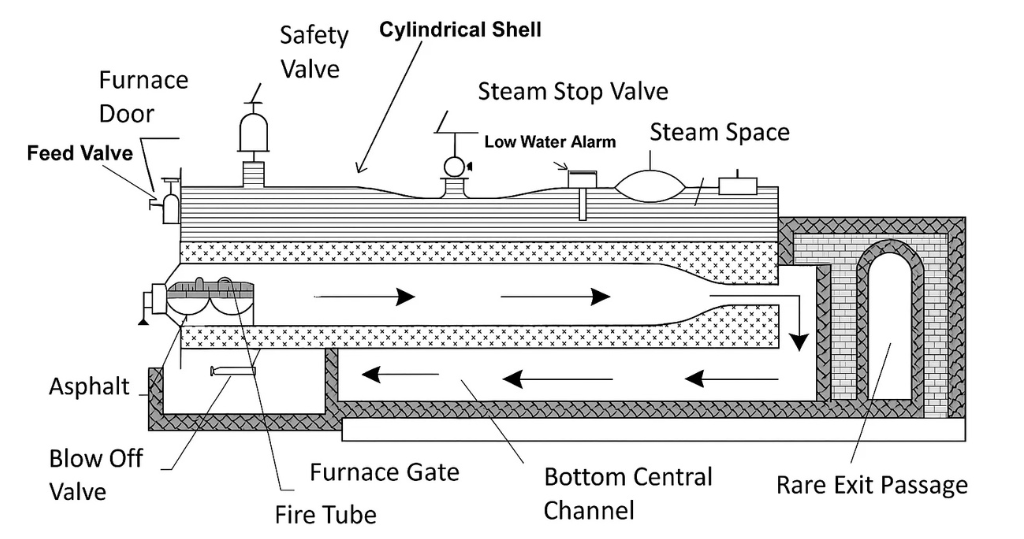

Construction of Lancashire Boiler

Cylindrical Shell: A horizontal shell placed over brickwork, half-filled with water, and the upper half reserved for steam.

Furnace Tubes: Two large internal furnace (flue) tubes run from one end of the shell to the other, surrounded by water for heat transfer.

Bottom and Side Flues: Brick-built passages that guide flue gases through the boiler for efficient heat transfer.

Grate: Located at the front end of each furnace tube, where solid fuel like coal is burned.

Fire Bridge: Brickwork at the end of the grate to prevent coal and ash from entering the furnace tubes.

Dampers: Sliding doors in side flues to control the flow of flue gases toward the chimney.

Mountings: Includes safety valve, steam stop valve, feed check valve, water level indicator, pressure gauge, blow-off valve, and manhole for operational safety.

Accessories: Economizer (preheats feed water using flue gas heat), superheater (raises steam temperature if required), and feed pump (supplies water to the boiler shell).

Working of Lancashire Boiler

The Lancashire Boiler operates on the principle of heat exchange and natural water circulation. Here’s how it works step by step:

Fuel Combustion: Solid fuel, such as coal, is fed through the fire door onto the grate at the front end of the furnace tubes. The fuel burns on the grate, producing hot flue gases.

Flow of Flue Gases: The hot gases first enter the fire tubes inside the boiler shell. As the gases travel from the front to the rear of the tubes, they transfer the majority of their heat (around 80–90%) to the surrounding water.

Secondary Heat Transfer: The flue gases then pass through the bottom flue and side flues, where they transfer an additional 6–10% of heat to the water. The brickwork surrounding the flues acts as a heat insulator while also guiding the gases efficiently.

Steam Formation: The water inside the shell absorbs heat and gradually turns into steam. Since the boiler is half-filled with water, the upper portion of the shell contains steam space. The natural circulation of water ensures uniform heating and prevents local overheating.

Steam Collection and Outlet: The dry steam rises to the top of the shell, where it can be extracted directly through the steam stop valve for industrial use. If a higher temperature of dry steam is required, it can pass through a superheater before use.

Water Feeding and Safety: The feed check valve ensures that water is supplied uniformly into the boiler, while safety devices like fusible plugs, water level indicators, and safety valves protect against overpressure and low water conditions.

Efficiency Consideration: By carefully controlling the flow of flue gases through dampers in the side flues and optimizing combustion in the grate, the boiler achieves a high thermal efficiency of 80–90%, making it highly economical for industrial steam generation.

Specification of Lancashire Boiler

Type: Low-pressure, fire-tube, natural circulation

Orientation: Horizontal, stationary

Fire Tubes: 2 (large diameter, slightly tapered at ends)

Pressure Range: 0.7–2 MPa (approx. 7–20 bar)

Steam Production: Up to 9,000 kg/hr

Efficiency: 65–90% depending on accessories and load

Drum Size: Diameter 4–6 meters, Length 9–10 meters

Fuel Type: Coal or solid fuels

Application of Lancashire Boiler

- The Lancashire Boiler is widely used in:

- Steam turbines and marine engines

- Locomotive engines for steam generation

- Industrial processes in paper, textile, sugar, and tire manufacturing

- Power plants for low-pressure steam generation

Advantages of Lancashire Boiler

- Easy to clean and maintain

- Reliable with large steam output

- Low electricity consumption due to natural circulation

- High thermal efficiency (80–90%)

- Simple design suitable for small to medium industries

- Capable of handling fluctuating load requirements

Disadvantages of Lancashire Boiler

- Requires a large floor space due to horizontal construction

- A low-pressure boiler cannot generate high-pressure steam

- The steam production rate is limited compared to water-tube boilers

- Leakage issues are possible over time

- Maintenance of brickwork is tedious

- Limited grate area due to the diameter of the fire tubes

Conclusion

The Lancashire Boiler remains a trusted industrial boiler due to its reliability, high efficiency, and simple operation. While it has limitations like low pressure and large floor space requirements, it is ideal for industries where large volumes of low-pressure steam are needed for turbines, engines, and process applications. With proper care and maintenance, the Lancashire Boiler continues to serve as a workhorse for industrial steam generation.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks