Different Types of Micrometer Screw Gauges and Their Uses

Published: 28 Nov 2025

In this article, we will discuss different types of micrometer screw gauges. Micrometer screw gauges are precise measuring tools used in engineering, manufacturing, and workshops. They help measure small dimensions accurately, like thickness, diameter, or depth. By reading this article, you will learn about various types of micrometers, their uses, and how they make measurements easier.

Different Types of Micrometer Screw Gauges

Here are some of the most common types of micrometer screw gauges and their uses:

1. Outside Micrometer

The outside micrometer is the most commonly used type of micrometer and it is ideal for measuring the external dimensions of rods, shafts, and mechanical components. It consists of a C-shaped frame, an anvil, and a spindle that moves towards the object to take precise readings. The measuring faces are usually made of hardened steel or carbide to prevent wear over time. This type of micrometer is widely used in workshops, manufacturing, and quality control because of its simplicity and high precision.

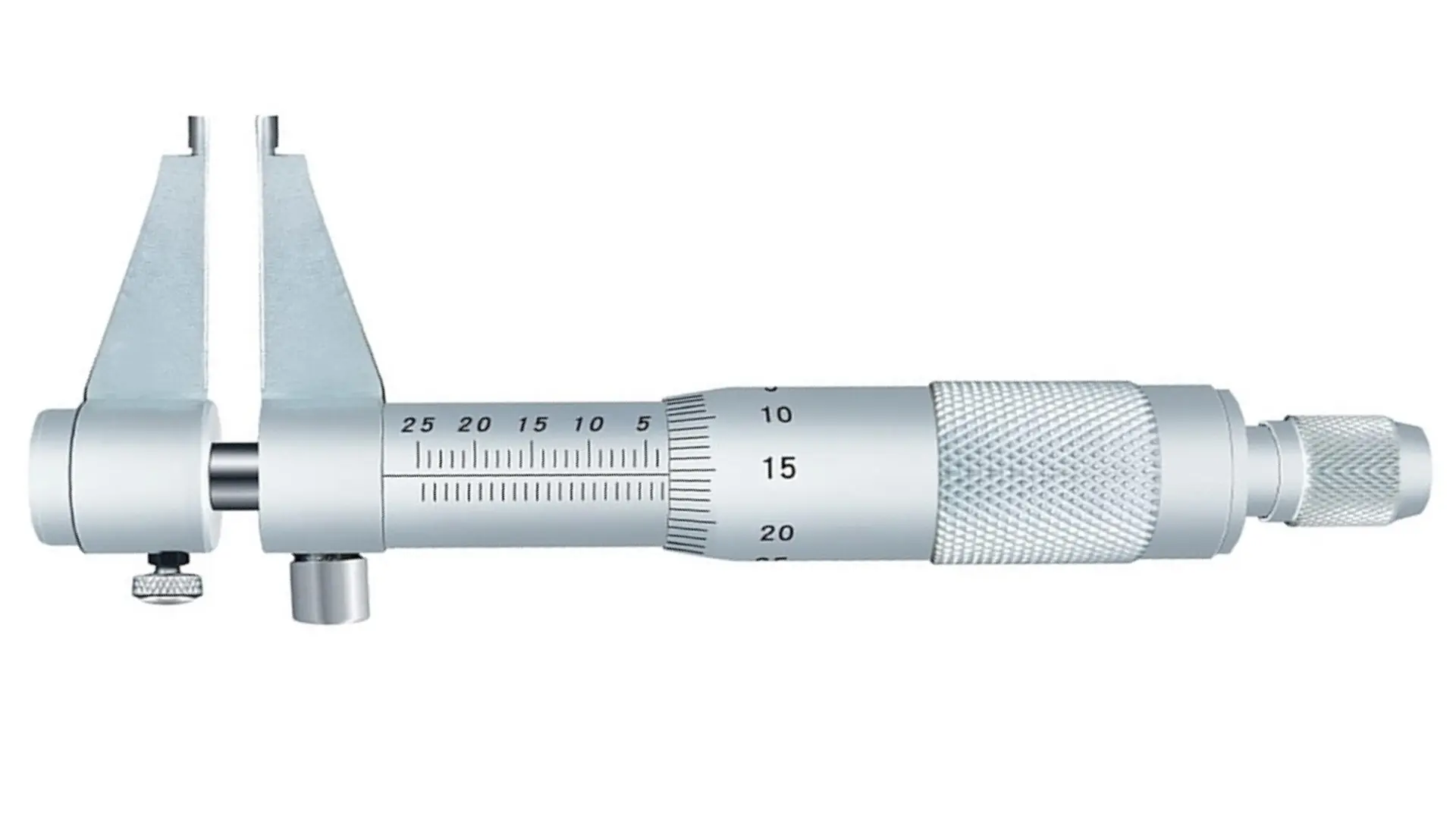

2. Inside Micrometer

Inside micrometers are used to measure the internal diameter of holes, cylinders, and tubes. They often come with 2-point or 3-point contact designs to ensure accuracy across different surfaces. Many inside micrometers include interchangeable measuring rods, making them suitable for a wide range of bore sizes. Proper alignment across the bore is critical, and skilled operators ensure accurate readings by checking both the axis and diameter simultaneously.

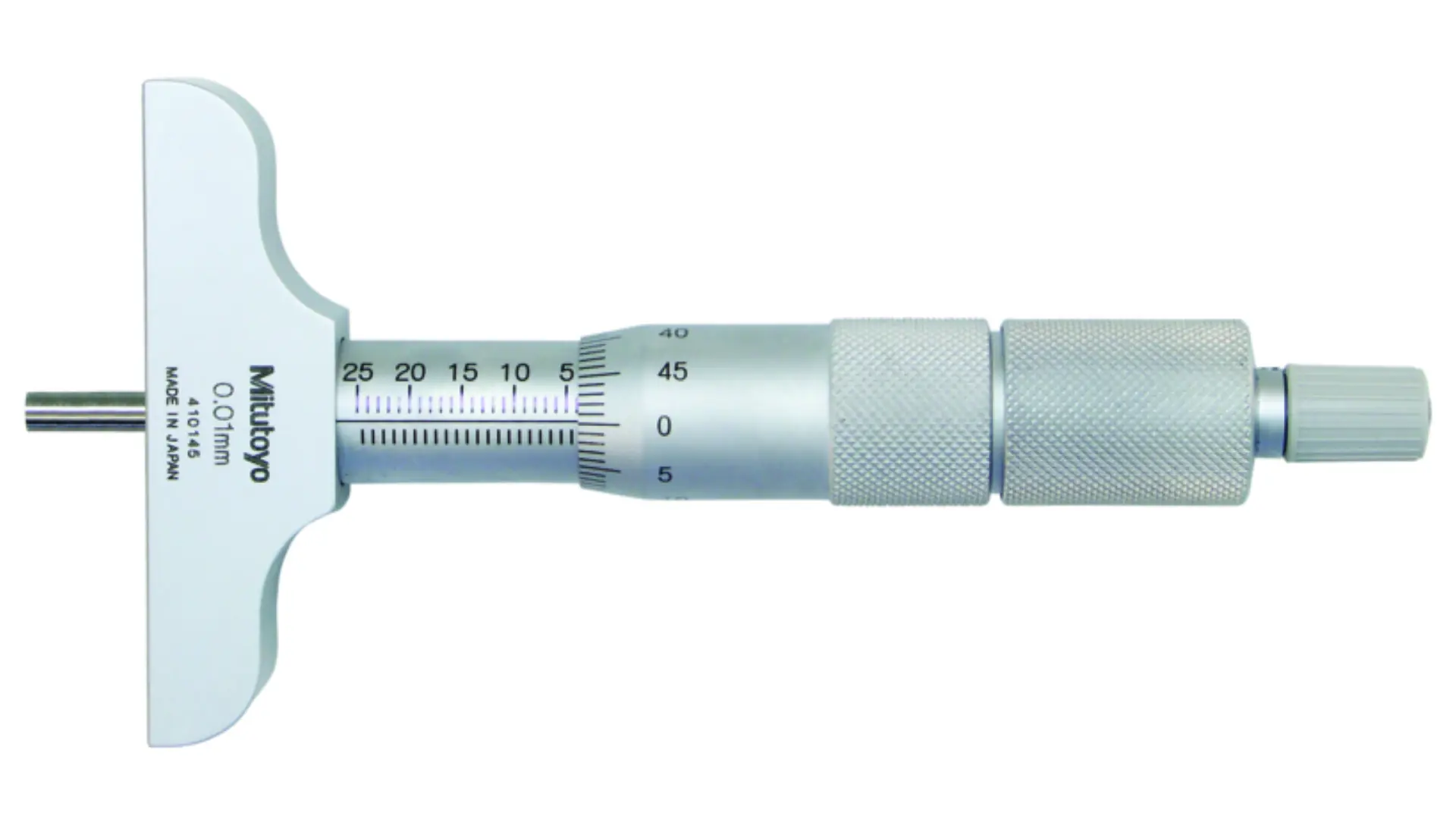

3. Micrometer Depth Gauge

The micrometer depth gauge measures the depth of holes, slots, steps, or recesses with high accuracy. It consists of a flat base and a movable spindle or rod that can be extended to reach varying depths. Interchangeable rods allow measurements across a wide range of depths, making this tool versatile for many workshop applications. Depth micrometers are particularly useful in metalworking, mold making, and machining processes where precise depth measurements are required.

4. Bench Micrometer

The bench micrometer is a stationary tool mounted on a workbench for high-precision measurements of parts that are difficult to measure by hand. It is ideal for repetitive tasks where consistent measurements are required. Bench micrometers typically have a large, stable frame that ensures accuracy even with heavier or awkwardly shaped workpieces. They are commonly used in workshops, quality control labs, and production facilities for consistent, reliable measurement results.

5. Screw Thread Micrometer

The screw thread micrometer is designed specifically for measuring the pitch diameter of screws and threaded components. It has a specialized spindle and anvil that fit precisely onto screw threads. Accurate measurement of thread dimensions is critical in fastener manufacturing and assembly processes. These micrometers are indispensable in mechanical workshops, ensuring threads meet strict tolerances and function correctly.

6. Vee – Anvil Micrometer

A Vee-anvil micrometer measures cylindrical or round objects with high precision. Its V-shaped anvil securely holds round workpieces, while the spindle moves to take accurate measurements. This type is ideal for rods, tubes, and small shafts, especially where conventional flat-anvil micrometers cannot grip properly. Vee-anvil micrometers are used in the engineering and machining industries to guarantee precise diameters for cylindrical components.

7. Digital Micrometer

Digital micrometers provide measurements on an electronic display for quick and easy reading. They reduce the chance of human error, allowing users to read dimensions without interpreting a scale manually. Digital micrometers often allow you to switch between metric and imperial units with a single button. Their convenience, accuracy, and speed make them increasingly popular in workshops, laboratories, and production lines.

8. Disk Micrometer

The disk micrometer is designed to measure grooves, slots, and narrow recesses that other micrometers cannot reach. Its disk-shaped anvil allows accurate contact with small features. These micrometers are especially useful in mechanical workshops and precision engineering. They ensure that even hard-to-reach areas are measured accurately without compromising the integrity of the component.

9. Tube Micrometer

Tube micrometers are specialized tools for measuring the diameter and thickness of tubes and cylindrical objects. They have a spindle and an anvil shaped to securely hold the tube in place while measuring. Tube micrometers are widely used in plumbing, mechanical workshops, and the manufacturing of pipe components. They ensure consistent and accurate measurements for cylindrical materials of varying diameters.

10. Blade Micrometer

The blade micrometer is designed to measure narrow slots, gaps, or recesses in components. Its blade-like anvil fits into spaces that standard micrometers cannot reach. This type is widely used in sheet metal work, the manufacturing of precision tools, and mechanical engineering. Blade micrometers provide reliable measurements in tight spaces, ensuring accuracy in challenging applications.

Conclusion

In conclusion, in this article, we covered different types of micrometer screw gauges in detail. We hope you have learned something helpful about these precise and useful measuring tools. Knowing the right type of micrometer can make your work easier and more accurate.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks