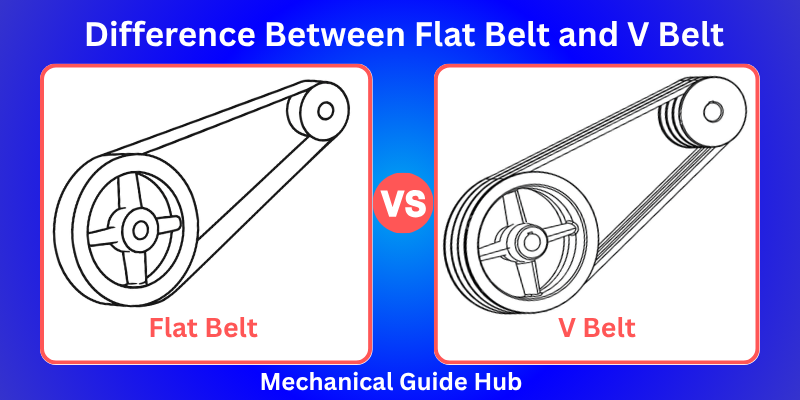

Difference Between Flat belt and V Belt

Published: 5 Jul 2025

Machines need power to move, and belts help deliver it from the motor to other parts. Among the many types of belts, flat belts and V belts are the most common. They both transfer power but in different ways. In this article, we’ll look at the difference between flat belt and V belt, helping you understand how each works and where it fits best.

Flat Belt

- Flat in shape with a wide, thin, rectangular body. The belt is much wider than it is thick.

- Only the bottom surface of the belt makes contact with the pulley. It has less grip.

- It has low grip and can slip when the load increases or the belt becomes loose.

- It works with simple, smooth pulleys that are cheap and quick to build.

- Works well at high speeds but can only carry light to medium loads.

- Very efficient at high speeds. It runs quietly and creates less friction.

- Can work over long distances, sometimes more than 10 to 15 meters.

- It can be used in both straight (open) and crossed setups to change direction.

- It may produce some noise, especially if it has joints or is loose on the pulley.

- Needs exact alignment. A small error can cause belt slip or wear.

- Slips easily under overload, which helps protect the motor.

- Needs more care, like cleaning and tension checking. Wears out faster over time.

- Mostly used horizontally, especially on machines with wide spacing.

- Found in conveyors, mills, and light-duty machines. Used in clean, dry areas.

- Performs efficiently with speed ratios up to 4:1. Ideal for simple speed control.

- Very low cost. It’s easy to buy and replace when it’s worn out.

- The flat belt moves the power by pressing flat against the pulley’s surface.

V Belt

- It has a V shape with slanted sides. It fits tightly into the matching pulley grooves.

- The slanted sides fit into the pulley groove, helping the belt hold tightly and not slip.

- It grips better due to its shape and wedge action, which stops slipping in most cases.

- V-belt needs special V-grooved pulleys. These are stronger but more costly than flat pulleys.

- It can carry heavy loads easily and works well at medium speeds with a strong grip.

- Slightly less efficient due to more contact, but stronger when more power is needed.

- This Belt is best for short distances, usually between 0.5 and 1 meter.

- It is only used in straight (open) setups. A crossed setup is not possible with V belts.

- It runs more quietly because it is endless and fits tightly into the groove.

- It can still work if the alignment is slightly off. It stays in place better.

- Grips tightly and rarely slips, but may still do so if the load is too heavy.

- It lasts longer with less care. It needs fewer checks and is more durable.

- Can work in any direction horizontally, vertically, or in angled positions.

- Found in cars, compressors, pumps, and industrial machines with heavy loads.

- It can go up to a 7:1 speed ratio. Good for high-power and torque applications.

- It is Costly because it gives better service and longer life on heavy-use machines.

- A wedge action between the belt and groove enables power transmission.

Conclusion

Understanding the difference between a flat belt and a V-belt helps you pick the right one.

To decide between a flat belt vs V belt, ask yourself the following:

- How far are the pulleys?

- How much load does the machine need?

- What speed and power are required?

This will help you pick the best belt for your machine. And that means better work and a longer life for your machine!

Please Write Your Comments

`

Comments (0)

INSTRUCTIONS:

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

INSTRUCTIONS:

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks