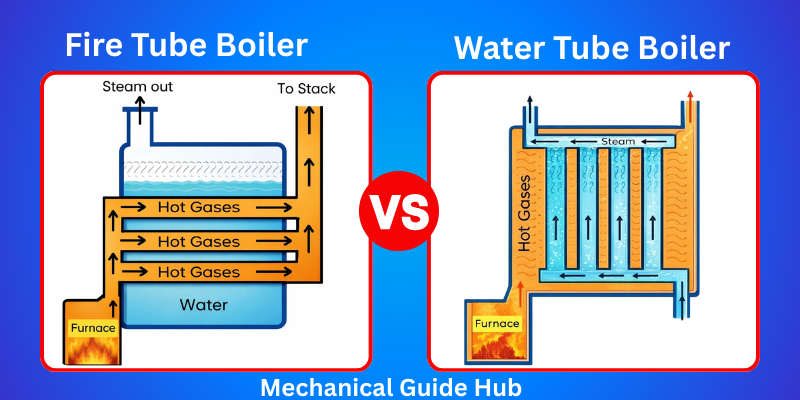

Difference Between Fire Tube and Water Tube Boiler

Published: 18 Jul 2025

Choosing the right boiler is important for safe and efficient steam production. One common question many ask is: What is the difference between a fire tube and a water tube boiler? Both are widely used in different industries, but they work differently and suit different needs. In this guide, we’ll break down the key differences to help you decide which type is best for your system.

Fire Tube Boiler

- The fire tube boiler produces steam by running hot gases through tubes enclosed in water.

- These boilers usually run at low to medium pressure, typically up to 250 psi.

- These boilers heat gradually due to their large water capacity.

- A fire tube boiler is great for small to medium operations.

- These boilers produce saturated steam at lower temperatures, making them perfect for basic heating needs.

- A fire tube boiler has a compact design, so it fits well in small spaces.

- Most fire tube models come as ready-made packages, making installation quick and easy.

- Ideal for small operations that need consistent steam..

- Because they have more water volume, fire tube boilers transfer heat at a slower rate.

- The boiler’s simple structure makes cleaning and maintenance easier for technicians.

- It holds more water, so damage is less likely to spread quickly.

- It can easily handle quick changes in steam demand, making it reliable during sudden load shifts.

- This type of boiler lasts a long time when used for simple, everyday steam needs.

- These boilers are cost-effective and easy to take care of.

- These are commonly used in textile factories, food processing plants, and central heating systems.

Water Tube Boiler

- In a water tube boiler, hot gases move around water-filled tubes to produce steam. This design helps the boiler produce steam quickly through fast heat transfer.

- It can handle very high pressure, even up to thousands of psi, which makes it perfect for heavy-duty industries like power plants and refineries.

- It heats up fast and produces steam quickly, which is ideal for time-sensitive operations.

- A water tube boiler is made for continuous use and can meet high steam demands in large setups.

- It can generate superheated steam at high temperatures.

- It’s larger in size, so it needs more space and a strong setup.

- They usually require installation at the location, which can take more time.

- These are more efficient for large operations where energy savings matter.

- With fast heat transfer, it gives quick steam recovery to meet steady demands.

- Due to its complex design, it needs expert care and regular maintenance.

- It is safer under high pressure, but it needs strict safety checks.

- Water Tube: Better at managing steady and high-pressure loads with precision.

- Built with strong materials to work in tough industrial conditions.

- It costs more at first, but it works better over time.

- Common in heavy industries like energy, oil, and chemicals.

Conclusion

Fire and water tube boilers each suit different needs. For simple, low-cost setups, go with a fire tube. For high pressure and performance, choose a water tube. Consider your space, steam needs, and budget. Still unsure? Contact a boiler expert for the right advice.

Please Write Your Comments

`

Comments (0)

INSTRUCTIONS:

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

INSTRUCTIONS:

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks