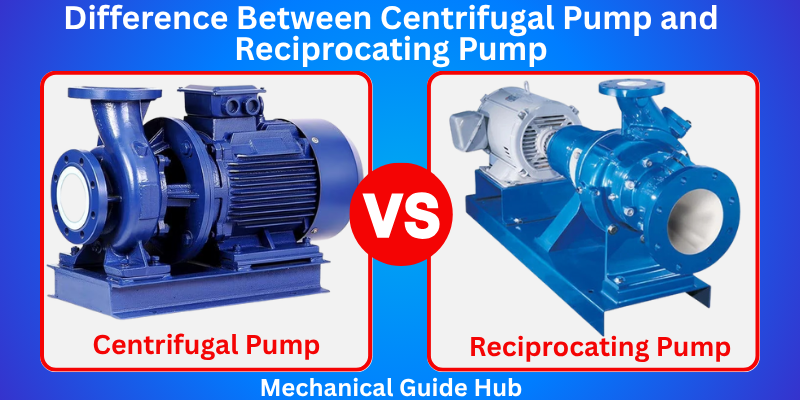

Difference Between Centrifugal Pump and Reciprocating Pump

Published: 17 Jul 2025

In this simple guide, we’ll explain the difference between a centrifugal pump and a reciprocating pump to help you understand which one is better for your job.

Centrifugal Pump:

- A centrifugal pump uses a rotating impeller to move liquid by creating centrifugal force. The fluid spins inside, then flows out.

- Provides a continuous and smooth passage of liquid.

- This is a rotodynamic pump.

- Used to pump large amounts of fluid.

- Centrifugal pumps have fewer moving parts, so they need less maintenance.

- Suitable for large liquid transfer with minimal pressure.

- Has limited suction lift; often needs priming.

- Requires priming before starting.

- Can be run at high speeds.

- Needs less maintenance and is easy to handle.

- Compact in size and good for small spaces.

- Quieter during operation.

- Cheaper to buy and install.

- Requires high starting torque.

- Uses more energy for partial loads.

- Works well with clean or slightly dirty liquids; not ideal for thick or solid-laden fluids.

- Cavitation is more likely when suction isn’t ideal.

- Efficiency ranges from 30–60%, depending on system conditions and design.

- Ideal for cooling systems, fire lines, irrigation, and industrial pipelines.

Reciprocating Pump

- A reciprocating pump uses a piston that moves back and forth inside a cylinder to create pressure and move fluid.

- Gives a pulsing flow with each piston move.

- This is a positive displacement pump.

- Reciprocating pumps are more efficient for small quantities and high-pressure tasks.

- Reciprocating pumps have more parts, like pistons and valves, which means more upkeep.

- Best for low-flow rate, high-pressure needs.

- Can create a strong vacuum, making it better for deep suction without priming

- Self-priming, so no need to fill with liquid first.

- Operates at lower speeds due to mechanical limitations.

- Needs regular maintenance and more attention.

- Larger and heavier, taking up more space due to complex mechanisms.

- Produces more noise and vibration due to piston movement.

- More expensive upfront and over time.

- Needs low starting torque.

- More energy-efficient, especially in small volumes, high-pressure systems.

- Can handle viscous, abrasive, or slurry fluids better.

- Less likely to cause cavitation.

- Can achieve over 85% efficiency consistently across their operating range.

- Commonly used in oil refineries, boilers, hydraulic jacks, and situations where high-pressure output is needed.

Conclusion

Picking the right pump can be easy when you know the basics. Now you’ve seen how centrifugal and reciprocating pumps are different, if you need a pump that runs fast and is easy to maintain, go for a centrifugal pump. A reciprocating pump is more appropriate if you need high pressure and power. Consider your pumping needs and how frequently you’ll use it. This will help you choose the right one without any trouble.

Please Write Your Comments

`

Comments (0)

INSTRUCTIONS:

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

INSTRUCTIONS:

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks