What Is a Cupola Furnace: Construction, Working, and Applications

Published: 13 Dec 2025

A cupola furnace is a vertical, cylindrical furnace widely used in foundries to melt cast iron, bronze, and other alloys. Its simple design and continuous operation make it cost-effective and efficient, allowing foundries to produce large quantities of molten metal. Even today, it remains a preferred choice for melting iron due to its high melting rate, easy operation, and effective impurity removal.

What is Cupola Furnace?

A cupola furnace is a type of melting furnace primarily used for cast iron. The name “cupola” comes from its dome-like shape at the top. It consists of a vertical steel shell lined with refractory materials to withstand high temperatures. Metals, fuel (coke), and flux (limestone) are added in layers from the top. Air is blown into the furnace through tuyeres, which helps ignite the fuel and generate the heat required for melting metal. Impurities in the metal combine with the flux to form slag, which is removed separately.

Construction of Cupola Furnace

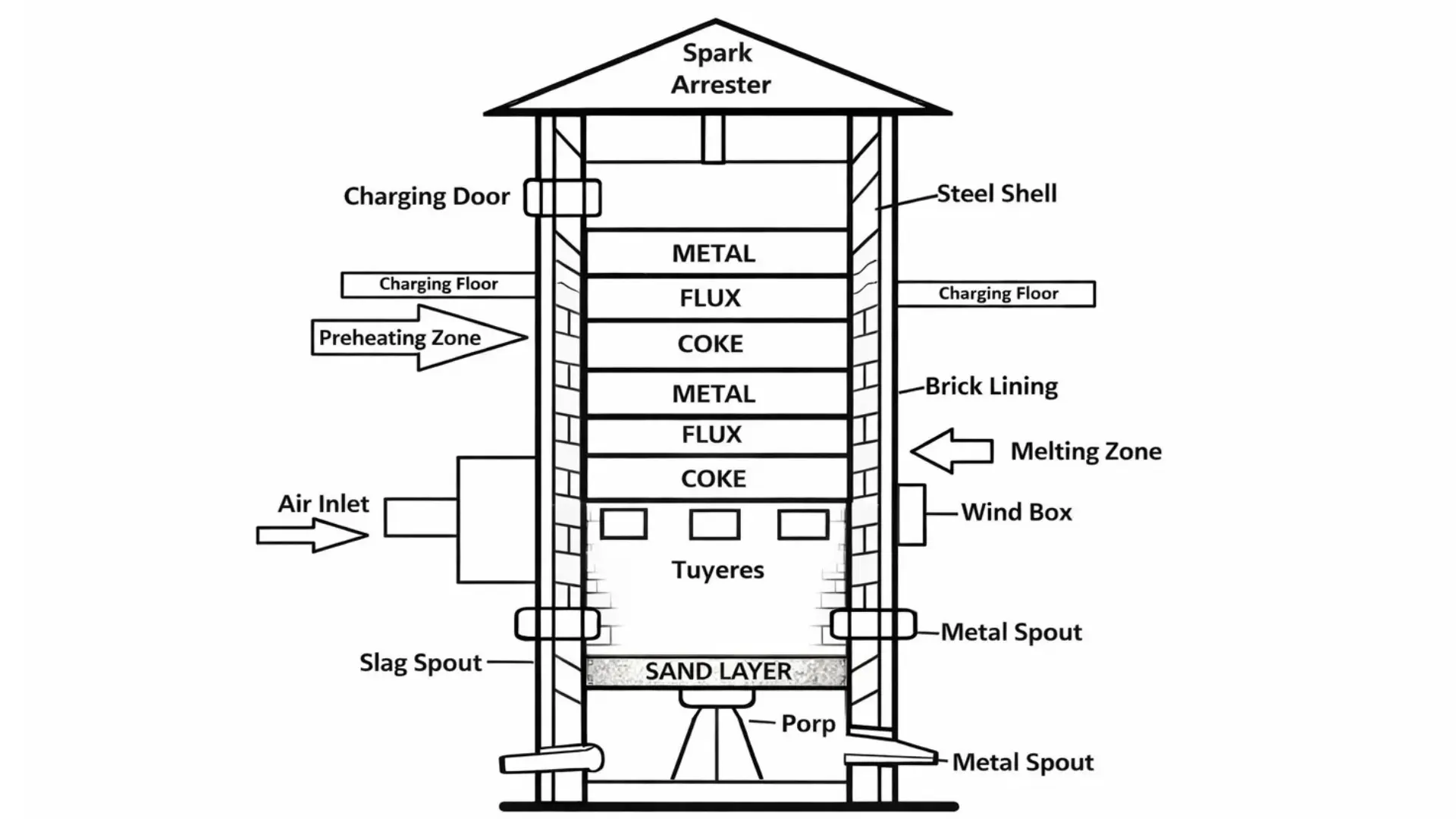

The cupola furnace is made up of several important parts, each serving a unique function to ensure efficient and continuous metal melting.

Cupola Furnace Diagram

image Source: gdmtechnics.com

Steel Shell & Refractory Lining: The furnace has a vertical steel cylinder that provides structural strength. Inside, it is lined with heat-resistant bricks to withstand extremely high temperatures during operation.

Legs & Concrete Base: Four sturdy legs support the furnace, keeping it stable and secure. They rest on a concrete base to evenly distribute the weight of the furnace and its contents.

Bottom Doors: Hinged doors are located at the bottom of the furnace. These allow easy removal of debris, slag for maintenance after the melting operation.

Wind Box & Blast Pipe: The windbox encircles the furnace bottom and connects to the blast pipe. This system supplies a steady air flow to help the coke fuel burn efficiently.

Charging Door: Positioned at the top of the furnace, the charging door is used to feed layers of metal, coke, and flux into the furnace. It allows operators to maintain a continuous supply of charge during operation.

Tuyeres: These are openings near the bottom of the furnace. They direct air from the wind box into the combustion zone to maintain high-temperature combustion for melting metal.

Tap Hole & Slag Hole: The tap hole allows molten metal to flow out into ladles for casting. The slag hole is used to remove impurities that form as slag during the melting process.

Spark Arrester: A cone-shaped structure on top of the furnace. It prevents sparks and dust from escaping while allowing waste gases to exit safely.

The furnace typically has a diameter of 450 mm to 2000 mm and can melt 1 to 30 tonnes of metal per hour, depending on its size and fuel-to-metal ratio.

Working of Cupola Furnace

Cupola furnaces can melt large volumes of metal continuously, making them suitable for industrial foundries as well as artistic casting operations.

- The cupola furnace operates on the counter-current principle, where hot gases move upward while metal moves downward.

- The bottom doors are closed, and the hearth is prepared with a sand bed to support the initial charge.

- Alternating layers of coke, metal (pig iron or scrap), and flux (limestone) are added from the top through the charging door.

- The coke is ignited, and air is supplied through tuyeres, producing high temperatures of 1500°C to 1850°C.

- Heat from the burning coke melts the metal, while the flux reacts with impurities to form slag, separating unwanted materials.

- Molten metal flows out through the tap hole, and slag is removed separately through the slag hole.

- Additional layers of charge are continuously added to maintain the furnace level, ensuring uninterrupted production.

This method ensures efficient melting and continuous production of high-quality molten metal.

Advantages of Cupola Furnace

- Continuous operation ensures high metal output.

- Low operating costs compared to other industrial furnaces.

- It can melt large quantities of metal quickly.

- Simple to operate, requiring minimal skilled labor.

- Efficient impurity removal using flux and slag.

- Versatile, capable of melting cast iron and some copper-based alloys.

- Compact design, saving floor space.

Disadvantages of Cupola Furnace

- Limited temperature control can affect the metal quality.

- Coke combustion produces emissions, which may harm the environment.

- Maintenance and repairs require skilled technicians.

- Not suitable for melting all types of metals, mainly cast iron and select alloys.

Applications of Cupola Furnace

- Foundries producing grey cast iron, malleable cast iron, and other alloys.

- Medium and large-scale metal melting operations.

- Copper-based alloy production.

- Artistic casting, including sculptures and decorative works.

- Continuous metal production using multiple cupolas in industrial foundries.

Conclusion

The cupola furnace is a reliable, efficient, and cost-effective furnace for melting cast iron and select alloys. Its vertical design, layered charging system, and air-assisted combustion make it suitable for continuous operation and high-volume metal production. While modern furnaces like electric induction systems provide more precise control, the cupola furnace remains a valuable tool for foundries due to its high output, simplicity, and effective slag removal.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks