Cornish Boiler Construction and Working

Published: 4 Oct 2025

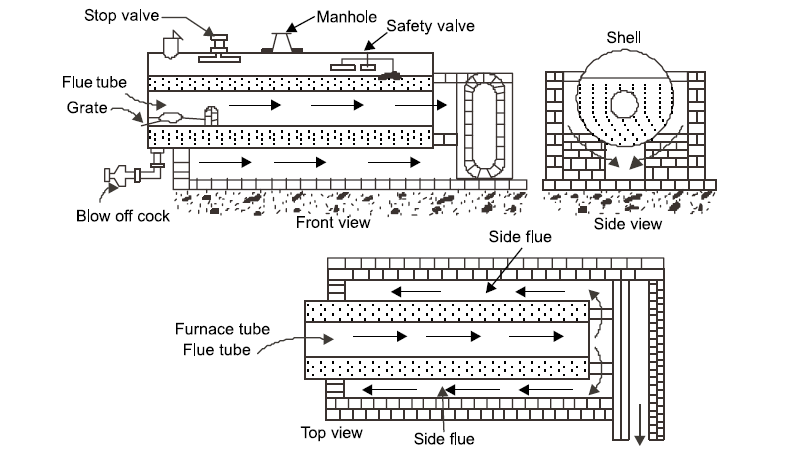

The Cornish boiler is one of the earliest types of fire-tube boilers, widely used in the 19th century for industrial steam generation. Even today, it serves as a great example of understanding the basics of boiler design, construction, and working principles. Known for its simple structure and effective performance, the Cornish boiler is a single-flue boiler that paved the way for more advanced boilers like the Lancashire boiler. Let’s explore what it is, how it works, and its applications.

What is Cornish Boiler?

A Cornish boiler is a type of fire tube boiler invented by Richard Trevithick in 1812. It is a horizontal, internally fired boiler with a single large-diameter fire tube running through its cylindrical shell. Water surrounds the tube, and heat transfer occurs as hot gases pass through the tube, converting the surrounding water into steam. The Cornish boiler operates at low to medium pressure and is mainly used in small and medium-scale industries.

Cornish Boiler Diagram

Construction of Cornish Boiler

The Cornish boiler has a simple yet strong design that makes it easy to build and operate. It mainly consists of a cylindrical horizontal shell made of steel plates, closed at both ends by circular end plates. The shell holds water around a single large fire tube, which runs longitudinally through the center.

Inside the fire tube lies the furnace and grate, where solid fuel such as coal is burnt. The furnace door allows fuel feeding, and the ash pit below the grate collects ash for easy removal. Above the furnace, a fusible plug is provided to prevent accidents in case of low water levels by extinguishing the fire.

The boiler is fitted with essential mountings and accessories such as:

Safety Valve – prevents excessive pressure buildup.

Pressure Gauge – shows the steam pressure inside the boiler.

Water Level Indicator – helps monitor the correct water level.

Feed Check Valve – regulates the supply of water into the boiler.

Blow-off Cock – removes sediments and impurities from the bottom.

The entire boiler is supported by brickwork, which not only holds it in position but also helps direct the flow of flue gases through the flues before they exit the chimney. This ensures maximum heat transfer from the hot gases to the surrounding water, making the Cornish boiler simple but effective for steam production.

Working of Cornish Boiler

The working principle of the Cornish boiler is straightforward:

- Coal is placed on the grate inside the furnace and ignited to produce hot gases.

- The flue gases first pass through the single large fire tube located at the center of the boiler shell.

- While moving through the fire tube, the gases transfer heat to the surrounding water.

- After leaving the fire tube, the gases enter the bottom flue beneath the boiler shell, where they transfer additional heat.

- The gases then move into the side flues on both sides of the shell for additional heat transfer.

- Finally, the gases travel towards the rear end and exit through the chimney.

- This three-pass system (fire tube → bottom flue → side flues) increases heat transfer efficiency.

- The water absorbs the heat and gradually converts it into steam, which collects in the steam space at the top.

- The steam is then supplied for industrial use through a steam stop valve.

- The boiler works on natural circulation of water without the need for pumps, making it reliable and cost-effective.

Specification of Cornish Boiler

- Type: Fire tube, internally fired, horizontal boiler

- Working Pressure: 6 – 10 bar

- Steam Capacity: Around 1350 kg/hr

- Efficiency: 60 – 70%

- Dimensions: 1.25 to 1.75 m in diameter and 4 to 7 m in length

- Fuel Used: Coal, wood, or other solid fuels

Application of Cornish Boiler

The Cornish boiler was widely used in the 19th and early 20th centuries for various purposes, such as:

- Textile, paper, and sugar industries for processing steam

- Small power plants and mills

- Pumping stations for water supply

- Mines for operating steam engines

- Early locomotives and marine engines

Advantages of Cornish Boiler

- Simple design and easy construction

- Requires less floor area compared to some other boilers

- Low maintenance cost

- Suitable for small-scale industries

Disadvantages of Cornish Boiler

- The steam generation rate is low

- Limited to low and medium-pressure applications

- Efficiency is lower compared to modern boilers

- Requires more time to raise steam

- Not suitable for large power requirements

Conclusion

The Cornish boiler holds an important place in the evolution of steam boilers. While it may not match the efficiency and output of modern boilers, its simple design made it reliable and widely used during the industrial revolution. For students and engineers, studying the Cornish boiler provides valuable insights into the fundamentals of boiler construction and operation.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks