Angle Grinder Parts Name and Their Functions

Published: 7 Oct 2025

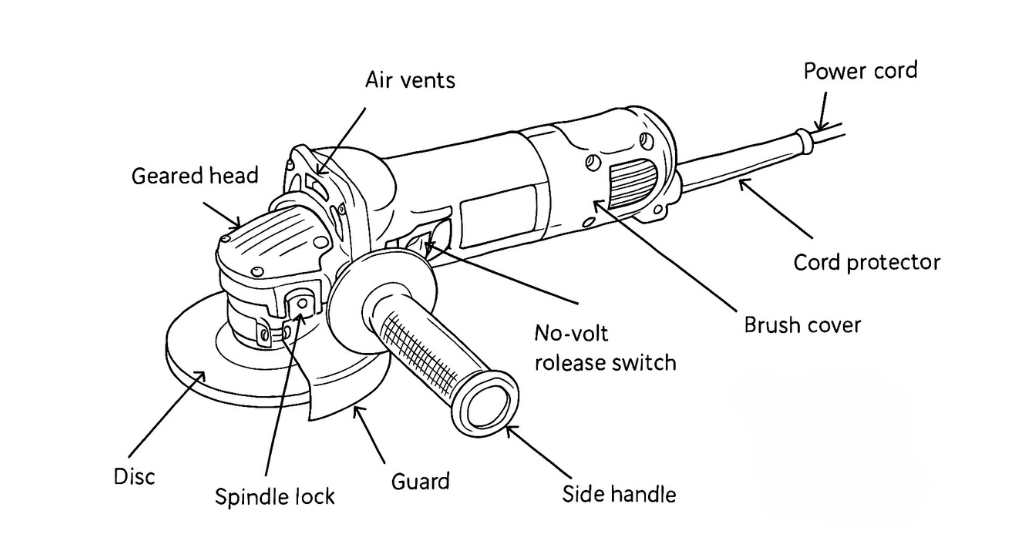

Angle grinders, also called side grinders or disc cutters, are essential tools for construction, metalwork, and home improvement. Knowing the angle grinder parts names and their functions helps you operate the tool safely, maintain it, and work more efficiently. Here’s a detailed guide to the most common parts of an angle grinder.

Angle Grinder Parts Name and Their Functions

1. Motor

The motor is the heart of the angle grinder and provides the power needed to rotate the discs at high speeds. It converts electrical energy into mechanical energy to drive the tool. The motor’s strength determines the grinder’s cutting and grinding capability.

2. Disc/Grinding Wheel

The disc, also called the grinding wheel, is the part that performs cutting, grinding, and polishing. Discs come in various types, such as cutting discs, grinding discs, flap discs, and wire brushes. They attach directly to the spindle for material removal tasks.

3. Disc Guard

The disc guard is a protective shield that partially covers the disc to protect the operator. It prevents sparks, debris, and fragments from causing injuries. Many guards are adjustable to suit different working angles.

4. Main Handle

The main handle provides a comfortable grip and allows the user to control the grinder effectively. Most controls, like the on/off switch and speed dial are located on this handle. It ensures stability and reduces fatigue during prolonged use.

5. Auxiliary (Side) Handle

The auxiliary or side handle offers extra support and better balance while using the grinder. It can usually be attached to either side of the tool for convenience. This handle helps maintain control during heavy-duty or precise work.

6. Spindle

The spindle is the rotating shaft that holds the disc securely in place. It connects the motor to the disc, transferring power efficiently. A strong and well-maintained spindle ensures smooth and safe operation.

7. Spindle Lock

The spindle lock keeps the spindle from turning when changing discs. It allows the user to safely and quickly remove or install a disc. This mechanism prevents accidents during maintenance.

8. On/Off Switch

The on/off switch controls the grinder’s power supply and is typically placed on the handle for easy access. It allows the operator to start and stop the tool safely. A responsive switch is crucial for operational control.

9. Speed Control Dial

Some angle grinders feature a speed control dial to adjust the disc’s rotation speed. This helps adapt the tool to different materials and tasks. It provides better precision and control during operation.

10. Arbor/Clamping Nut

The arbor or clamping nut secures the disc to the spindle. Tightening this nut ensures the disc remains stable during use. A properly installed nut prevents slippage and enhances safety.

11. Cord or Battery Pack

Corded grinders rely on a power cord, while cordless models use a rechargeable battery pack. This part supplies energy to the motor for operation. Battery-powered grinders offer portability, whereas corded models provide continuous power.

12. Brush Cover and Carbon Brushes

Carbon brushes conduct electricity to the motor and wear out over time. The brush cover protects these components and allows easy replacement. Maintaining brushes ensures consistent motor performance and longer tool life.

Conclusion

These are the most common parts of an angle grinder, and each plays a crucial role in its performance. From the motor and disc to the spindle, handles, and guards, understanding these components improves safety, efficiency, and control. Knowing these parts also helps you maintain the tool and get better results for every project.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks