Thermal Power Plant: Components, Working, Site Selection, Advantages & Disadvantages

Published: 12 Dec 2025

Thermal power plants are the backbone of electricity generation, converting heat from fuel into electrical energy to meet the growing energy demands of modern society. In this article, we will discuss what a thermal power plant is, its main components, how it works, the factors to consider for site selection, and its advantages and disadvantages.

What is a Thermal Power Plant?

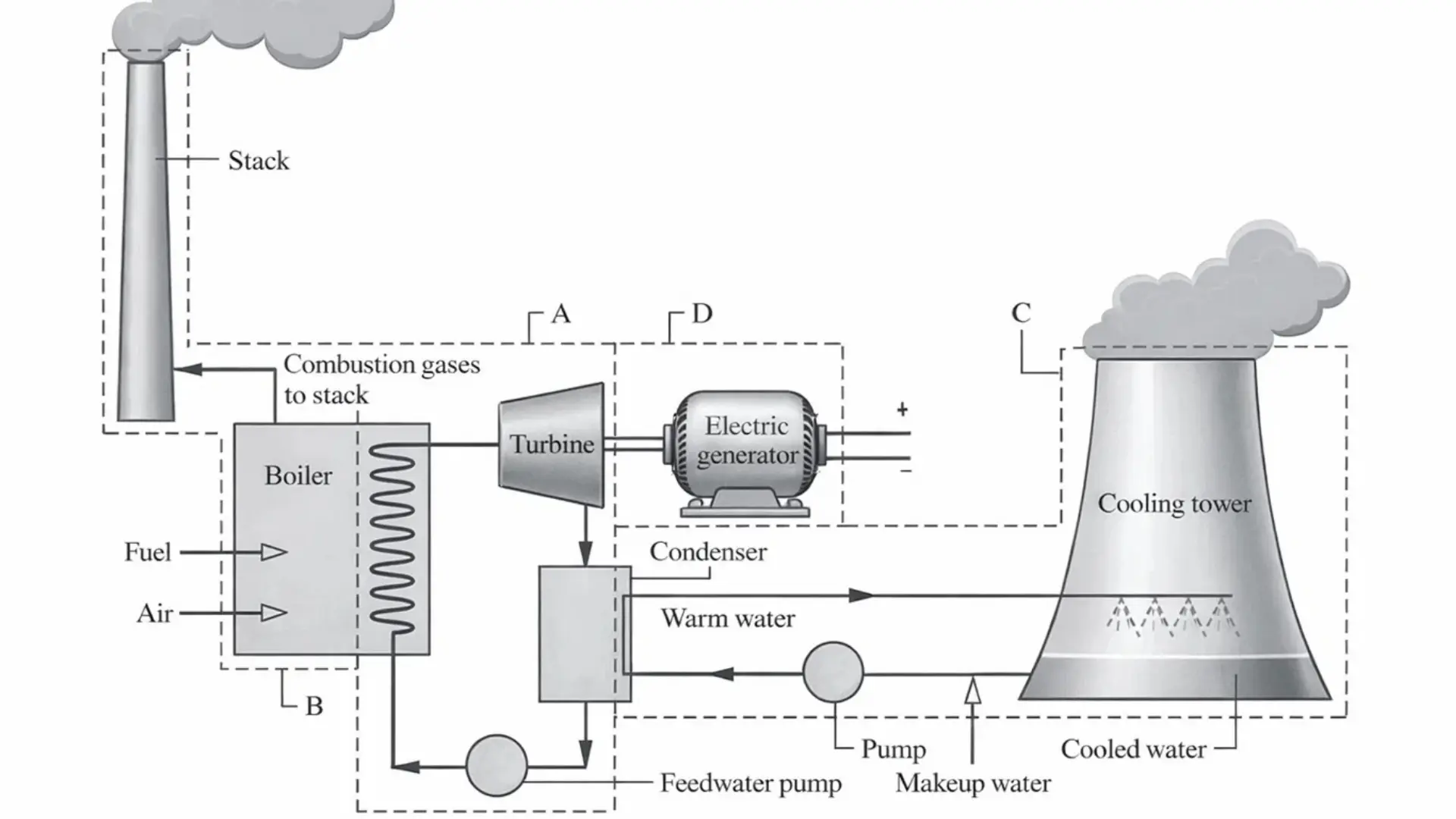

A thermal power plant is a facility that generates electricity by converting heat energy from the combustion of fossil fuels into mechanical energy and then into electrical energy. The process involves heating water in a boiler to produce high-pressure steam. This steam drives turbines, which are connected to generators to produce electricity. Thermal power plants are commonly coal-based, but oil and natural gas are also used as fuel sources. They are considered base-load power plants, supplying continuous electricity to the grid.

Components of Thermal Power Plant

A modern thermal power plant consists of several key components, each performing an important function:

Coal Handling Plant: The coal handling plant ensures a continuous and regulated supply of coal to the boiler. It includes unloading, crushing, screening, storage, and transfer systems to efficiently manage fuel supply.

Boiler: The boiler is the heart of a thermal power plant, where heat from burning fuel converts water into high-pressure steam. The generated steam powers the turbines, which in turn produce electricity.

Superheater: The superheater heats saturated steam from the boiler to extremely high temperatures. This prevents moisture in the steam, protecting turbine blades and improving overall plant efficiency.

Economiser: An economiser is a type of heat exchanger that preheats the feed water before it enters the boiler. It uses waste heat from flue gases, saving fuel and increasing the thermal efficiency of the plant.

Air Preheater: The air preheater heats the incoming air used for coal combustion. By recovering heat from flue gases improves fuel efficiency and reduces energy loss in the boiler.

Steam Turbines: Steam turbines convert the thermal energy of high-pressure steam into mechanical energy. The rotating shaft of the turbine drives the generator to produce electricity.

Alternator (Generator): The alternator is coupled to the turbine shaft and converts mechanical energy into electrical energy. It delivers electricity to the grid via transformers and circuit breakers.

Condenser and Cooling System: The condenser cools the exhaust steam from the turbine, converting it back into water. Cooling towers or circulating water systems are used to remove heat efficiently.

Feedwater System: The feedwater system treats and circulates the condensed water back into the boiler. This closed-loop system maintains water quality and improves the plant’s efficiency.

Exciter: The exciter is a DC generator that provides power to the alternator’s rotor. It ensures stable voltage generation and smooth operation of the power plant.

Chimney: The chimney safely releases flue gases into the atmosphere. It is designed to minimize pollution and includes access for inspection, lightning protection, and proper draught for combustion.

Working of Thermal Power Plant

The working of a thermal power plant involves several stages

- Coal, oil, or natural gas is burned in the boiler and furnace to produce heat. This combustion releases thermal energy, which is essential for converting water into high-pressure steam.

- Water in the boiler tubes absorbs the heat from the combustion and turns it into high-temperature, high-pressure steam. This steam is initially wet and then further heated in the superheater to prevent moisture formation.

- The superheater raises the temperature of saturated steam beyond its boiling point. Superheated steam ensures maximum efficiency when driving turbines and protects turbine blades from erosion.

- The high-pressure steam is directed onto the blades of the steam turbine. As the steam expands, it rotates the turbine shaft, converting thermal energy into mechanical energy.

- The turbine shaft is connected to a generator (alternator). Mechanical energy from the turbine is converted into electrical energy, which is then supplied to the power grid.

- After passing through the turbine, low-pressure steam enters the condenser. Cooling water from a river, lake, or cooling tower removes heat, condensing the steam back into the water.

- The condensed water, known as condensate, is pumped back into the boiler through the feedwater system. Additional makeup water is added as needed to maintain the required water level.

- Air is supplied to the furnace using forced draught fans, and flue gases are expelled through the chimney after passing through the economiser and air preheater. This ensures proper combustion and energy recovery.

- Cooling towers or water circuits remove excess heat from the condenser. This keeps the condenser pressure low, improving turbine efficiency and maintaining the closed-loop water cycle.

- Automatic and manual controls regulate boiler pressure, turbine speed, and generator output. Continuous monitoring ensures safe, efficient, and stable plant operation.

Site Selection of Thermal Power Plant

Choosing the right site is critical for efficient and sustainable operation. Important factors include:

Availability of Coal: Proximity to high-quality coal reduces transportation costs and pollution.

Availability of Water: Needed for steam generation, cooling, and ash handling.

Adequate Land: Enough space for boilers, turbines, generators, ash disposal, and future expansion.

Proximity to Load Centers: Reduces transmission and distribution losses.

Distance from Residential Areas: Minimizes environmental and health impacts.

Transport Facilities: Rail, road, or waterways for coal supply and equipment transport.

Advantages of Thermal Power Plant

- Large-scale electricity generation capability.

- Can operate continuously as a base-load plant.

- Lower fuel cost compared to nuclear power plants.

- Can be installed near load centers, reducing transmission losses.

- Requires less land compared to hydroelectric plants.

- Capable of responding quickly to changing electricity demand.

Disadvantages of Thermal Power Plant

- High operating and maintenance costs.

- Air pollution due to flue gases and ash.

- Large water requirement for steam generation and cooling.

- Coal handling and ash disposal are labor-intensive and costly.

- Efficiency drops significantly below 75% of full load.

- Construction and commissioning require a long time.

Conclusion

In conclusion, thermal power plants are a major source of electricity, converting heat from fuels such as coal, oil, or gas into power. They are reliable and capable of producing large amounts of energy. However, they also contribute to pollution and consume natural resources. With proper planning, efficient fuel use, and environmental measures, their impact can be reduced. Despite these challenges, they remain an important source of energy today.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks