Loeffler Boiler Construction and Working

Published: 28 Oct 2025

The Loeffler Boiler is a high-pressure, water tube, and forced circulation boiler widely used for power generation. It was developed to solve the common problem of salt and sediment deposition that occurred in earlier designs, such as the LaMont Boiler. By using superheated steam instead of water for evaporation, the Loeffler Boiler improves efficiency, prevents scaling, and ensures a smooth, continuous supply of steam for turbines. This innovative design makes it ideal for large industrial applications and modern power plants.

What is Loeffler Boiler

A Loeffler Boiler is a type of water tube boiler that operates at high pressure and uses forced circulation to generate steam. It features an internal furnace where fuel such as coal is burned to produce heat. In this system, around 65% of the superheated steam generated is used to evaporate the feed water inside the evaporating drum, while the remaining 35% is supplied to the steam turbine for power generation.

Unlike conventional boilers, where water circulates through tubes, the Loeffler Boiler prevents the flow of water through its tubes, thereby avoiding salt and scale formation. This design ensures higher efficiency and longer operational life, even when using saline feed water.

Construction of Loeffler Boiler

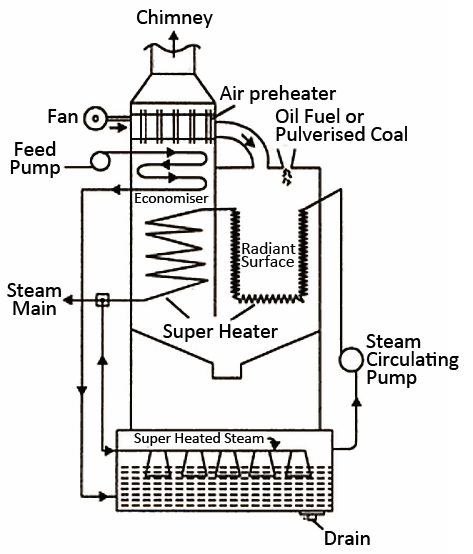

The Loeffler Boiler consists of several key components, each playing an essential role in efficient steam generation.

Loeffler Boiler Diagram

Feed Pump: Delivers water into the system from the economizer to maintain pressure and flow.

Economizer: Preheats feed water using hot flue gases to improve boiler efficiency.

Evaporating Drum: Located at the lower section of the boiler, it contains a mixing nozzle where feed water and superheated steam mix to form saturated steam.

Steam Circulating Pump: Circulates steam from the evaporating drum to the radiant and convective superheaters.

Radiant Superheater: Increases the temperature of steam using radiant heat from the furnace.

Convective Superheater: Further raises steam temperature through convection, reaching up to 500°C.

Air Preheater: Preheats the air before it enters the combustion chamber for improved fuel combustion.

Blower: Supplies hot air for combustion inside the furnace.

Turbine: Converts superheated steam energy into mechanical work for electricity generation.

Mixing Nozzle: Blends steam from the superheater with feed water to promote efficient evaporation.

Chimney: Releases exhaust gases safely into the atmosphere.

Fusible Plug and Water Level Indicator: Safety components that monitor and protect the boiler from overheating and water level issues.

Together, these components ensure effective heat transfer, high efficiency, and safe operation.

Working of Loeffler Boiler

The working principle of the Loeffler Boiler is based on evaporating feed water using superheated steam instead of direct furnace heat.

Here’s how it works step-by-step:

- Feed water is pumped through the economizer, where it absorbs heat from flue gases.

- The preheated water then enters the evaporating drum.

- About 65–70% of the superheated steam from the superheater is injected into this drum through a mixing nozzle.

- This high-energy steam mixes with the feed water, instantly converting it into saturated steam.

- The steam circulating pump draws this saturated steam and sends it to the radiant superheater, where it gets heated through radiation.

- The steam then passes through the convection superheater, which further raises its temperature to approximately 500°C.

- Around 30–35% of the superheated steam is sent to a steam turbine to produce power.

- The rest of the steam returns to the evaporating drum to continue the evaporation process, maintaining a closed-loop system.

This continuous circulation of steam ensures uniform heating, eliminates salt deposits, and improves overall boiler efficiency.

Specification of Loeffler Boiler

Type: Water tube, forced circulation, high-pressure boiler

Steam Capacity: Up to 100 tons/hour

Working Pressure: Around 140 bar

Steam Temperature: Up to 500°C

Circulation Type: Forced circulation

Fuel Used: Coal or solid fuels

These specifications make it suitable for heavy industrial operations and large power generation setups.

Application of Loeffler Boiler

The Loeffler Boiler is used in industries where continuous and high-pressure steam is required. Some key applications include:

- Thermal power plants for turbine operation

- Industrial steam generation systems

- Marine power units for large ships

- Electric power generation setups

- Its ability to handle saline feed water and maintain high efficiency under pressure makes it perfect for large-scale applications.

Advantages of Loeffler Boiler

- Eliminates the problem of salt and scale formation inside tubes.

- Compact design and high thermal efficiency.

- Can handle saline feedwater effectively.

- Provides steady steam output even with load variations.

- High circulation rate ensures uniform temperature and efficient heat transfer.

- Quick response to load changes, suitable for power generation.

- Better heat recovery due to radiant and convective superheaters.

Disadvantages of Loeffler Boiler

- Bubble formation inside heating tubes can reduce heat transfer efficiency.

- The system requires perfectly sealed high-pressure gas passages to function safely.

- Bulky and expensive, mainly due to the large evaporating drum.

- Requires skilled supervision and maintenance for proper operation.

- The construction is complex compared to natural circulation boilers.

Conclusion

In conclusion, the Loeffler Boiler stands out as an efficient and reliable high-pressure boiler, designed to overcome the limitations of earlier boiler types like the LaMont Boiler. With its forced circulation system, no scaling issue, and high thermal efficiency, it’s one of the best choices for modern power plants. Although it’s more complex and costly to build, its superior performance, compact design, and ability to use saline feedwater make it a valuable asset for large-scale industrial steam generation and electricity production.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks