Scotch Marine Boiler: Construction, Working, Types, and Advantages

Published: 21 Oct 2025

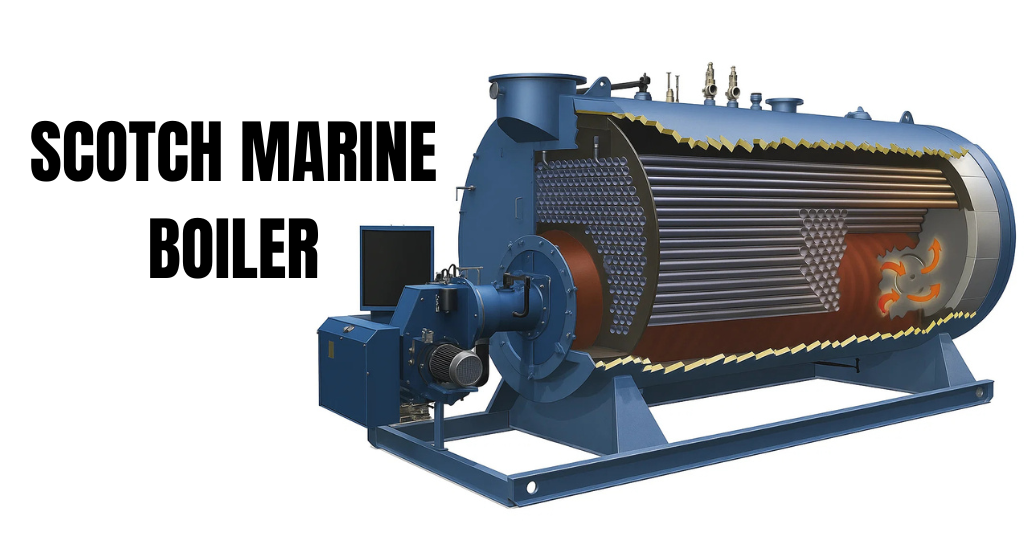

The Scotch Marine Boiler is one of the most popular fire-tube boilers used in marine applications. Known for its compact design, high efficiency, and versatility in using any type of water, it has been a trusted choice for ships and marine systems for over a century. This boiler doesn’t require brickwork or external flues, making it simple, reliable, and easy to maintain — ideal for marine conditions where space and efficiency are paramount.

What is Scotch Marine Boiler?

A Scotch Marine Boiler is a fire-tube boiler where hot gases pass through tubes that are surrounded by water. The heat from these gases converts the water into steam.

This type of boiler is also called a tank-type or shell-type boiler, and it was first used on ships around 1862. Its strong and compact structure makes it suitable for marine engines, cargo ships, and naval vessels.

Construction of Scotch Marine Boiler

The construction of a Scotch Marine Boiler is simple yet strong. It has several key parts that help it work efficiently:

Boiler Shell: The main body of the boiler is made of steel plates. It holds both water and steam and provides strength to handle pressure.

Furnace: Located inside the water space, it is where the fuel burns. Most Scotch boilers have three or four furnaces, and each is corrugated to handle heat expansion.

Combustion Chamber: The space where fuel gases burn completely. It is surrounded by water to absorb heat quickly.

Smoke Tubes: These horizontal tubes carry the hot flue gases from the combustion chamber to the chimney. As gases move through them, they transfer heat to the water around them.

Chimney: The chimney releases smoke and exhaust gases safely into the atmosphere.

Smokebox: It connects the smoke tubes to the chimney and helps in cleaning and maintenance.

All these parts are placed inside a cylindrical shell to make the boiler compact and efficient.

Working of Scotch Marine Boiler

The Scotch Marine Boiler works on the fire-tube principle. Its operation can be explained step by step:

- Fuel is fed into the furnace through a fire hole and ignited.

- The burning fuel produces hot gases, which move into the combustion chamber.

- These gases then pass through the smoke tubes, heating the surrounding water.

- The water absorbs heat and turns it into steam.

- The steam collects at the top of the boiler shell and is then used for marine engines or other purposes.

- Finally, the flue gases exit through the chimney into the air.

Because water surrounds the furnace, smoke tubes, and combustion chamber, the boiler has a large heating surface, ensuring quick and efficient steam generation.

Types of Scotch Marine Boiler

There are mainly two types of Scotch Marine Boilers:

Single-Ended Scotch Marine Boiler:

It has one end with one to four furnaces.

Its length is usually up to 3.5 meters.

Compact and best suited for smaller marine engines.

Double-Ended Scotch Marine Boiler:

It has furnaces on both ends, with two to four furnaces on each side.

The length is around 6.5 meters.

Commonly used on large ships where more steam is needed.

Specification of Scotch Marine Boiler

Here are some general specifications of a Scotch Marine Boiler:

Type: Fire-tube boiler

Orientation: Horizontal

Number of furnaces: 1 to 4 (single-ended) or 2 to 4 on each end (double-ended)

Shell diameter: 2.5 to 3.5 meters

Length: Up to 3.5 m (single-ended), 6.5 m (double-ended)

Working pressure: Around 8 to 16 bar

Steam generation rate: Moderate

Fuel used: Coal, oil, or gas

Application of Scotch Marine Boiler

The Scotch Marine Boiler is mainly used in marine applications, but it also finds use in other industries.

Common applications include:

- Ships and naval vessels

- Cargo and passenger ships

- Small power plants

- Industrial steam generation

Its compactness and high efficiency make it ideal for places where space is limited but reliable steam output is needed.

Advantages of Scotch Marine Boiler

- Compact and space-saving design.

- Easy to install and maintain.

- Can operate with different types of water.

- Provides high operational efficiency.

- No need for external flues or brickwork.

- Strong structure suitable for marine operations.

Disadvantages of Scotch Marine Boiler

- Requires more floor space compared to modern water-tube boilers.

- Load changes are hard to handle quickly.

- Not suitable for high-pressure steam production.

- Slower steam generation than water-tube types.

- Needs regular cleaning and maintenance for efficiency.

Conclusion

The Scotch Marine Boiler is a classic and reliable boiler known for its durability, simplicity, and efficiency. Even though modern water-tube boilers have replaced it in many areas, it remains a trusted choice in marine engineering. Its compact design, ability to use any water, and ease of maintenance make it one of the most successful fire-tube boilers ever built.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks