Hydraulic Bottle Jack Parts Name and Their Functions

Published: 14 Oct 2025

A hydraulic bottle jack is a powerful tool that helps lift heavy vehicles or equipment with very little effort. It works on the simple principle of hydraulic pressure, using oil and force to raise a load safely. But have you ever wondered what makes this small tool so strong? Understanding the hydraulic bottle jack parts name and their functions can help you use it properly and maintain it for a long life. Let’s look at each part and see how they work together to lift heavy weights smoothly.

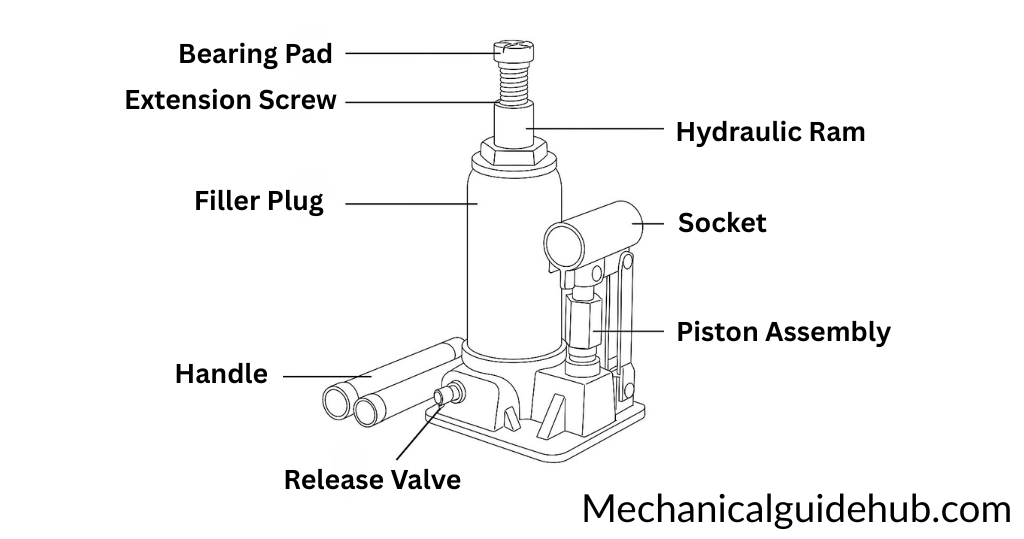

Hydraulic Bottle Jack Parts Name and Their Functions

Every hydraulic bottle jack is built with key components that work as one system. Each part has a special job that ensures smooth operation, safety, and stability. Below are the main parts and their functions explained in simple terms.

1. Bearing Pad

The bearing pad is the flat, round surface at the top of the jack. It touches the vehicle or object you want to lift. Its main job is to hold the load firmly in place without it slipping. A strong bearing pad also helps spread the weight evenly, making the lifting process safe and stable.

2. Extension Screw

The extension screw sits on top of the hydraulic ram. You can twist it to add a bit more lifting height when needed. It is very useful when working with vehicles or objects that sit high on the ground. This screw gives flexibility to adjust the jack to different lift points easily.

3. Filler Plug

The filler plug is a small but very important part. It covers the opening where you add or refill hydraulic oil. If the oil level drops, the jack will not work properly. By keeping the filler plug tight and checking oil levels often, you can make sure the jack always runs smoothly.

4. Handle

The handle is used to pump out the jack. It gives you the power to create hydraulic pressure. Most bottle jacks come with two handle pieces, a short one for tight spaces and a longer one for better leverage. By moving the handle up and down, you push fluid through the system, which helps lift the load.

5. Release Valve

The release valve controls when the jack lifts or lowers. When you tighten it, the jack builds pressure to raise the load. When you loosen it, hydraulic fluid returns to the reservoir, allowing the load to come down slowly and safely. It is one of the most important parts for smooth and controlled operation.

6. Hydraulic Ram

The hydraulic ram is the main lifting part. It rises out of the jack’s body as the pressure inside increases. The ram holds the heavy load in place until you release the pressure. Made from strong metal, it must be smooth and clean to prevent oil leaks and ensure steady movement.

7. Socket

The socket connects the handle to the pumping system. When you move the handle, the socket moves up and down, helping the piston build pressure. It is a small part, but without it, the jack would not be able to pump or lift at all.

8. Piston Assembly

The piston assembly pushes hydraulic fluid from the reservoir into the ram cylinder. Each pump stroke increases pressure inside the jack. This pressure is what lifts the load. The piston assembly must remain clean and well-lubricated to function efficiently and prevent internal damage.

Conclusion

A hydraulic bottle jack may look simple, but it is a clever mix of strong parts working in harmony. From the bearing pad that grips the load to the piston assembly that creates lifting power, each part plays a vital role. Knowing the names and functions of hydraulic bottle jack parts helps you use the tool safely, maintain it effectively, and achieve long-lasting performance. Always handle it with care, check the oil level, and keep it clean so your jack stays strong and ready whenever you need it.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks