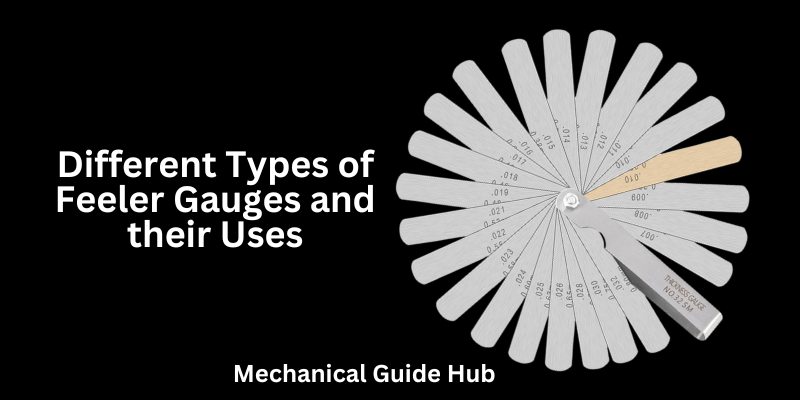

Different Types of Feeler Gauges and Their Uses

Published: 17 Jul 2025

What is a Feeler Gauge?

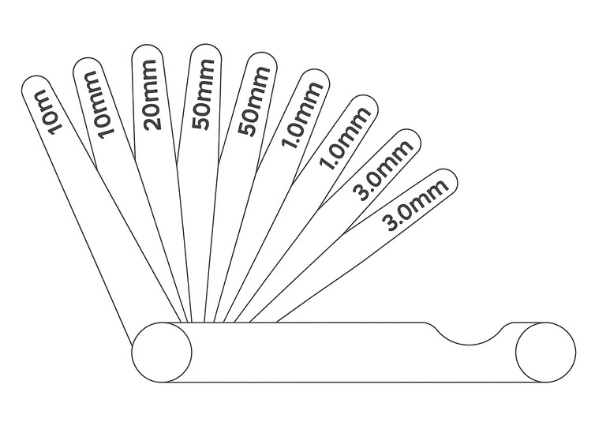

Feeler Gauge Diagram

A feeler gauge measures the small gap or space between two parts or surfaces. It looks like a folding knife, but instead of blades, it has thin metal strips of different thicknesses. These strips, called blades or leaves, are labeled with numbers that indicate their thickness.

Different Types of Feeler Gauge?

Feeler gauges come in different shapes and materials. Each type is designed for specific tasks, depending on the space, accuracy, and material required. Here are the most common types:

1. Wire Type Feeler Gauges

These gauges use small, rounded wires instead of flat blades. They’re perfect for checking circular gaps like the space inside spark plug holes or fuel injectors.

2. Blade Feeler Gauges

The most common type. These are flat metal strips with thickness markings on each blade. They fold out like a pocket knife and are perfect for general use in mechanical or engine work.

3. Thin Feeler Gauges

These are extra-slim blades used when the gap is very narrow and space is tight. They’re useful for fixing or checking tiny parts in precision tools and machines.

4. Angled Feeler Gauges

These gauges have blades bent at an angle. This makes it easier to reach hard-to-access areas, like deep inside an engine or behind machine parts.

5. Feeler Gauge Sets

They include a full range of blades, often sized between 0.04 mm and 1 mm or higher. They’re perfect for professionals who need a full range of sizes in one compact tool.

6. Plastic Feeler Gauges

Made from durable plastic, these gauges are non-magnetic and ideal for working with electronics or sensitive components. They’re also good for environments where metal might cause scratches or damage.

What is a Feeler Gauge Used For

Here are a few common uses:

Checking spark Plug gaps: In engines, the spark plug gap must be accurate for the engine to run smoothly.

Measuring valve clearances: In cars and motorcycles, valves must open and close at precise timings. The gauge helps ensure the space between the valve and the camshaft is correct.

Setting air gaps in machines: Many machines have parts that need a tiny space for movement or air flow.

Checking gear clearances: When gears turn, there must be just the right amount of space between them. Too much or too little space can cause wear and noise.

How to Read a Feeler Gauge

- Pick a blade and read the number on it – that tells you its thickness.

- Slide the blade into the gap you’re checking.

- If it fits just right—not too tight or too loose—that’s your gap size.

- If it doesn’t fit well, try a thinner or thicker blade until it feels perfect.

FAQs

This tool is sometimes known as a gap or thickness gauge.

The least count is the smallest thickness the tool can measure. It’s usually 0.01 mm.

This means the blade has a thickness of 0.15 mm.

Prices vary, but most sets cost between $5 and $20, depending on the brand and quality.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks