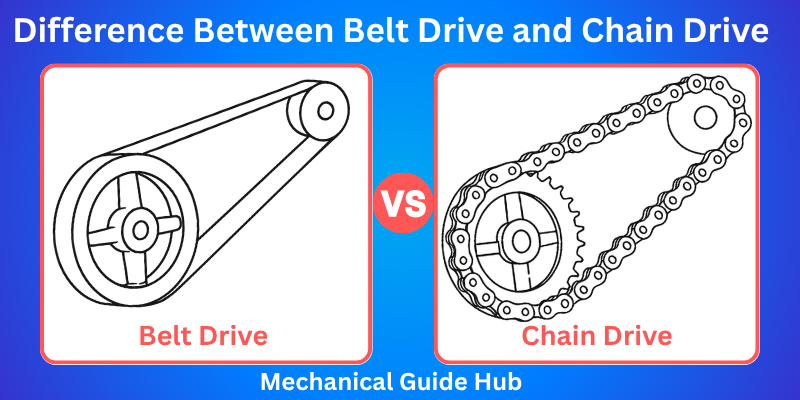

Difference Between Belt Drive and Chain Drive

Published: 29 Jun 2025

Belt and chain drives are popular ways to move parts in a machine. They both transfer motion from one shaft to another, but in different ways and for different needs. If you’re not sure which one to use, this guide will help you understand the difference between belt drive and chain drive in a simple way.

Belt Drive vs Chain Drive: The Essential Comparison

Belt Drive

- It works by looping a flexible belt over pulleys. The belt moves as the pulley spins.

- Belts are made from rubber, leather, or synthetic materials. They’re soft and flexible.

- It can run over long distances, which makes it ideal for machines where shafts are far apart.

- It may slip under load because it relies on friction between the belt and pulley.

- Slightly less efficient (90–95%) due to slippage and belt stretch.

- It is not ideal for high-torque tasks. It works best in low- to medium-load situations.

- Belt drives operate quietly with minimal vibration.

- It require less maintenance. They don’t need lubrication and are easy to replace.

- It has a shorter lifespan and may degrade faster under heat or friction.

- Belts are Cheaper to install and maintain.

- Mostly used in machines like washing machines, dryers, HVAC systems, and light-duty conveyors.

Chain Drive

- It uses a metal chain that runs over sprockets. The sprockets have teeth that lock with the chain, so there’s no slipping.

- Chains are made of metal links, usually steel, making them strong and tough.

- It works best when the distance between shafts is short or moderate.

- No slippage happens because the chain is locked into the sprockets by their teeth.

- More efficient (95–98%) because there’s no slip, and power is transmitted directly.

- It is excellent at handling heavy torque. Ideal for industrial or heavy-duty machines.

- Chain drives produce more noise and vibration due to metal contact and chain tension.

- Chains demand frequent lubrication, tensioning, and cleaning to prevent wear.

- Chains last longer in tough conditions and heavy work.

- It is more expensive to buy and set up, but it lasts longer in rough conditions.

- Mostly seen in motorcycles, bicycles, and heavy machines in factories.

Conclusion

If you want something quiet, simple, and low-maintenance for light loads over longer distances, a belt drive is perfect. But if you’re dealing with heavy loads, high torque, and rough conditions, a chain drive is your best bet.

Both systems have strengths and weaknesses. Now that you understand the full picture of belt drive vs chain drive, you’re ready to make the right choice for your project or machine.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks